In the fast-paced world of manufacturing, quality control is one of the most important aspects to focus on. Machine vision AOI (Automated Optical Inspection), paired with AI Visual Inspection and AI in visual inspection, is rapidly transforming how industries ensure that products meet their high-quality standards. These technologies automate the inspection process, ensuring more precision, speed, and efficiency compared to traditional methods. This blog will dive into why machine vision AOI is the future of automated quality control and how it’s helping industries worldwide enhance their production processes.

NOTE: Machine vision AOI and AI Visual Inspection are undoubtedly the future of automated quality control. By improving accuracy, speed, and efficiency, these technologies are transforming how manufacturers inspect products, reduce defects, and optimize their production processes. As AI in visual inspection continues to evolve, it will only become more capable of handling complex inspections, ensuring that businesses can meet the ever-growing demands for high-quality products. By embracing machine vision AOI, industries can stay ahead of the curve and deliver exceptional products consistently.

What Is Machine Vision AOI?

The Basics of Machine Vision AOI

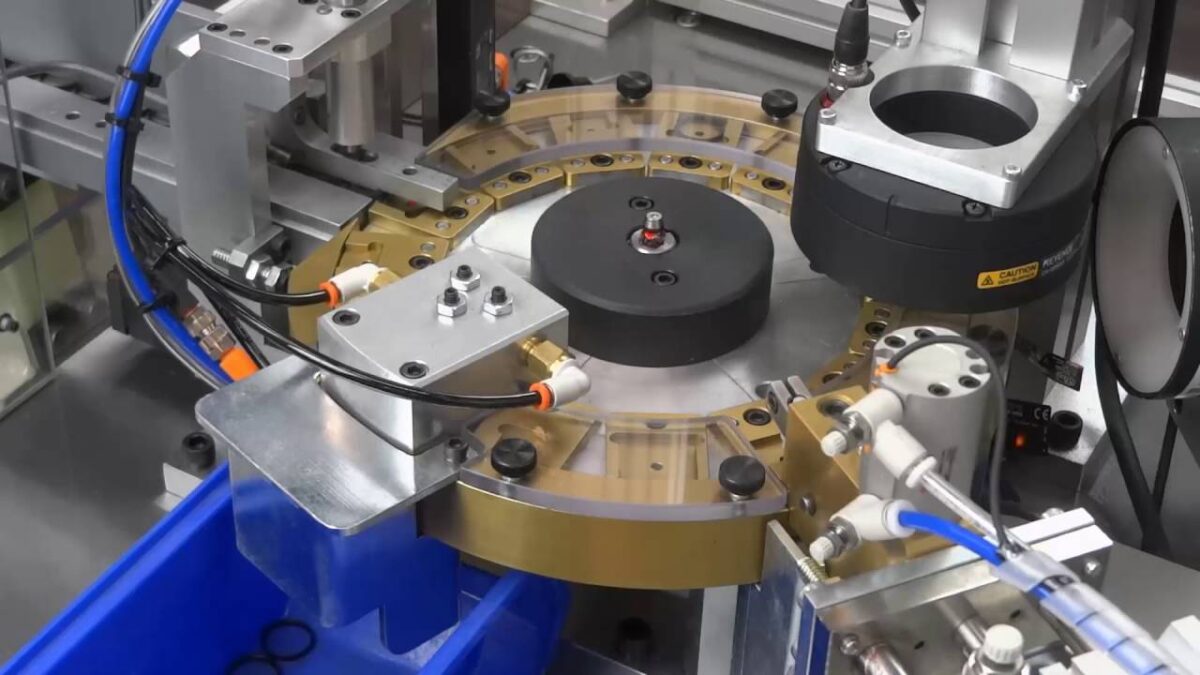

Machine vision AOI uses cameras, sensors, and specialized software to perform visual inspections of products as they pass through a production line. It captures high-resolution images of items and analyzes them to detect any defects, variations, or imperfections. With the integration of AI Visual Inspection, the system becomes even smarter, allowing it to identify a wider range of defects and learn from its previous inspections.

This system is already becoming a game-changer in industries such as electronics, automotive, and packaging, where precision is critical. For example, in electronics, machine vision AOI can be used to inspect the tiny components on circuit boards, ensuring that there are no faults before they are assembled into larger devices.

How AI Visual Inspection Enhances Machine Vision AOI

While machine vision AOI can automatically inspect products, adding AI Visual Inspection makes the system more powerful. AI algorithms can analyze patterns in the data collected from the images to detect defects more accurately. Unlike traditional visual inspection systems that rely on fixed parameters, AI in visual inspection can learn from the mistakes and improve its performance over time, making it an invaluable tool in quality control.

The Benefits of Machine Vision AOI in Quality Control

1. Increased Accuracy and Precision

One of the main reasons why machine vision AOI is the future of quality control is its unparalleled accuracy. Unlike humans, who can become tired and make errors, machine vision systems can maintain high levels of precision throughout the entire production process. The system uses advanced algorithms and high-resolution cameras to detect even the smallest defects that might go unnoticed by human inspectors.

For instance, in the automotive industry, machine vision AOI can identify the tiniest scratches on metal surfaces or monitor the alignment of components in a car assembly line. By catching these issues early, manufacturers can avoid larger problems later on and improve the overall quality of the final product.

2. Faster Production Times

With machine vision AOI, manufacturers can inspect products at a much faster rate than manual inspection. The system operates continuously, allowing manufacturers to speed up production lines without sacrificing quality. Instead of stopping the line for manual inspections or relying on human workers to scan for defects, machine vision AOI performs these tasks instantly, enabling products to be inspected in real time.

This increased speed of inspection helps manufacturers meet high demands and tight deadlines without compromising quality. In high-volume industries like electronics or food packaging, this ability to quickly identify defects leads to more efficient workflows and higher productivity.

3. Reduced Labor Costs

Traditionally, quality control requires a dedicated team of workers to inspect products manually. This process is time-consuming and often requires multiple rounds of checks, leading to high labor costs. With machine vision AOI, the need for human inspection is reduced, as the system can handle the bulk of the inspection work automatically.

By implementing AI Visual Inspection, manufacturers can further reduce the reliance on human workers for quality checks, allowing them to allocate their labor to more strategic tasks. Over time, this reduction in labor costs can significantly boost the profitability of the business.

4. Consistent and Reliable Inspections

Human inspectors can vary in their attention to detail, leading to inconsistencies in the inspection process. Machine vision AOI, on the other hand, offers consistent and reliable performance, eliminating the possibility of human error. The system’s accuracy does not fluctuate based on tiredness or distractions, ensuring that every product is inspected with the same level of precision.

As a result, manufacturers can be confident that their products meet quality standards every single time. Whether it’s checking for alignment, surface defects, or missing components, machine vision AOI ensures that no detail is overlooked.

How AI Visual Inspection Powers Machine Vision AOI

The Role of AI in Improving Inspection Quality

AI in visual inspection is what truly sets machine vision AOI apart from traditional systems. While machine vision can detect defects based on predefined criteria, AI Visual Inspection adds a layer of flexibility by allowing the system to learn and improve over time. AI-powered algorithms analyze defect patterns, adjust the inspection parameters as needed, and continuously enhance the system’s performance.

This ability to “learn” means that the AI Visual Inspection system becomes more efficient with each use. For example, it can learn from previous inspections and adapt to detect new types of defects that may have been missed initially. Over time, this leads to improved accuracy, fewer false positives, and greater overall efficiency in the inspection process.

The Impact of AI Visual Inspection on Defect Detection

By using AI in visual inspection, the system can spot defects that are difficult for humans to detect. These can include microcracks, surface inconsistencies, or subtle variations in color. Machine vision AOI combined with AI is capable of identifying defects that would normally require human intervention, making it invaluable in industries where precision is critical, such as medical device manufacturing or semiconductor production.

AI-powered systems can also reduce the number of false positives, meaning fewer products are incorrectly flagged as defective. This ensures that only truly faulty items are rejected, preventing unnecessary waste and improving the overall efficiency of the manufacturing process.

The Future of Machine Vision AOI in Quality Control

Ongoing Advancements in AI and Machine Vision

The future of machine vision AOI looks promising as ongoing advancements in AI and image processing technology continue to push the boundaries of what’s possible. With AI becoming more advanced, we can expect even more accurate defect detection, faster processing times, and more adaptable systems that can handle complex inspection tasks.

As these technologies evolve, they will be able to detect even more subtle defects, automate additional processes, and integrate seamlessly with other parts of the manufacturing workflow, such as inventory management and production planning.

Expanding Applications Across Industries

As industries continue to adopt machine vision AOI, we can expect its application to expand beyond traditional manufacturing fields. From healthcare to food production, AI-powered visual inspection will become increasingly important for ensuring product quality and safety. With new technologies emerging every day, machine vision AOI is set to revolutionize quality control across a variety of sectors.

For more insightful articles related to this topic, feel free to visit getbacklinkseo