In the ever-evolving world of modern manufacturing, the demand for ultra-precise, efficient, and complex part production is at an all-time high. For industries ranging from aerospace and medical to automotive and robotics, 5 axis CNC machining services have become the cornerstone of high-performance component manufacturing. Offering superior flexibility and accuracy, this advanced technology is reshaping what manufacturers can accomplish.

What Are 5 Axis CNC Machining Services?

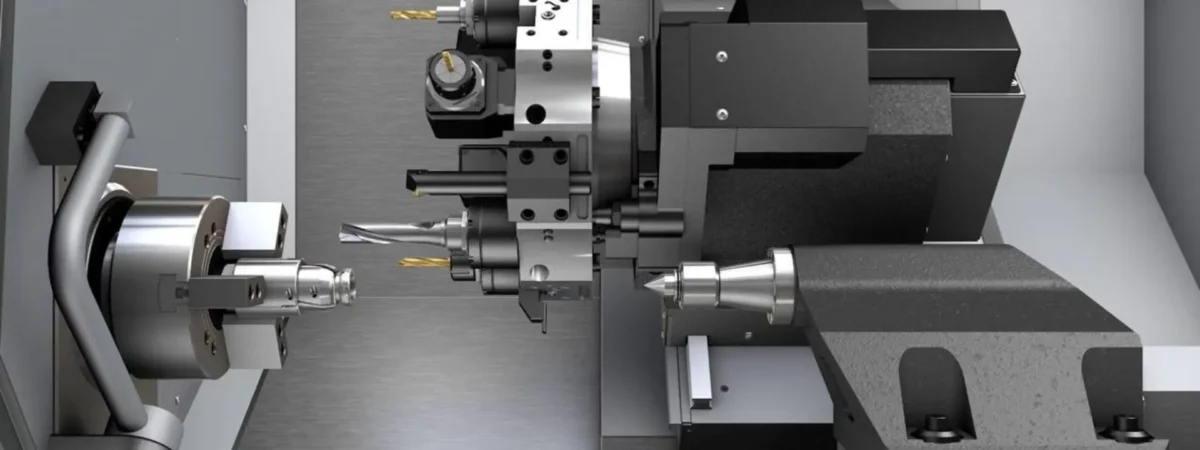

5 axis CNC machining services refer to the use of computer numerical control (CNC) machines capable of moving a tool or a part along five different axes simultaneously. Unlike 3-axis machines, which only move along the X, Y, and Z axes, 5-axis machines can rotate on two additional axes, known as A and B (or sometimes C). This added movement allows for more complex geometry, improved surface finishes, and reduced setup times.

These capabilities make 5 axis CNC machining services the ideal solution for producing parts that demand both intricacy and precision in a single operation.

The Growing Importance of Precision in Modern Manufacturing

Today’s industries demand components with extremely tight tolerances and sophisticated geometries. Whether it’s medical implants, aerospace brackets, or intricate mold components, manufacturers cannot afford deviations. This is where precision 5 axis CNC machining becomes crucial.

By allowing simultaneous multi-directional movement, this process eliminates the need for multiple setups. The result is not just a more efficient process but also fewer errors, tighter tolerances, and better consistency—key requirements in sectors where failure isn’t an option.

Advantages of 5 Axis CNC Machining Over Traditional Methods

1. Enhanced Geometrical Flexibility

With 5 axis CNC machining services, engineers can design without limitation. The machine’s flexibility supports the creation of undercuts, complex curves, and intricate angles—all in a single setup.

2. Improved Accuracy and Efficiency

Traditional machines require repositioning the part multiple times, introducing alignment errors. Multi-directional cutting in 5 axis CNC machining services allows for uninterrupted workflow, maintaining the part’s datum and minimizing cumulative errors.

3. Reduced Production Time

Fewer setups mean faster production. Parts that would take days with multiple machines can now be completed in hours using a single 5 axis CNC machining service process.

Custom 5 Axis Machining Services for Diverse Industries

One of the greatest strengths of this technology lies in its adaptability. Custom 5 axis machining services can be tailored to suit a wide range of industries, including:

-

Aerospace: High-stress components like turbine blades and structural parts benefit from tight tolerances.

-

Medical: Surgical instruments and orthopedic implants demand exceptional precision and surface finish.

-

Automotive: High-performance engine parts and transmission components are crafted with accuracy.

-

Robotics: The need for lightweight and complex parts makes custom 5 axis machining services indispensable.

Whether a company requires a single prototype or a full production run, 5 axis CNC machining services offer scalable solutions with unmatched precision.

How a 5 Axis CNC Machining Company Delivers Excellence

Partnering with the right 5 axis CNC machining company is essential for achieving reliable outcomes. Skilled machinists and engineers utilize CAD/CAM software to plan every step of the process, optimizing tool paths and minimizing material waste.

Moreover, a reputable 5 axis CNC machining company invests in the latest machinery and quality control systems, ensuring every part meets strict industry standards. This kind of expertise and technology empowers manufacturers to push the limits of what’s possible.

The Role of Multi-Axis CNC Machining Services in Prototyping and Production

Multi-axis CNC machining services go beyond just complexity—they also bring flexibility. Whether you’re working on an initial prototype or scaling to full production, this approach allows for rapid transitions and minimal downtime.

With multi-axis CNC machining services, design iterations can be implemented quickly, helping companies stay agile and competitive in fast-moving markets. Additionally, these services are ideal for producing small to medium-sized batches of highly specialized parts with high repeatability.

Key Features of Precision 5 Axis CNC Machining

1. Unmatched Accuracy

With movements across five axes, precision 5 axis CNC machining delivers tighter tolerances than traditional methods, often reaching micrometer-level precision.

2. Superior Surface Finish

Reduced vibration and fewer repositions result in smoother finishes, which is especially important for aesthetic or functional parts that require minimal post-processing.

3. Complex Contour Capabilities

Precision 5 axis CNC machining enables production of parts with dynamic contours and intricate profiles—something that is extremely difficult or impossible with 3-axis machining.

Choosing the Right Partner for 5 Axis CNC Machining Services

Not all machining partners are created equal. When selecting a provider, consider the following:

-

Experience: A seasoned provider has tackled a wide range of materials and part geometries.

-

Technology: Look for facilities equipped with modern machines and CAM software.

-

Quality Assurance: Ensure they follow ISO standards and have in-house inspection equipment.

Your choice of a 5 axis CNC machining company can greatly impact the success of your project, especially when accuracy and efficiency are critical.

Scaling Up With Custom 5 Axis Machining Services

As demand increases, having access to custom 5 axis machining services allows companies to scale without compromising on quality. Whether it’s adapting existing designs or introducing new product lines, the versatility of 5-axis machining supports growth at every stage.

In-house teams can collaborate closely with the machining partner to ensure optimal material use, cost-efficiency, and timely delivery—advantages that are vital in today’s competitive landscape.

Future-Proofing With Multi-Axis CNC Machining Services

Technology is moving fast, and manufacturing is no exception. As part geometries become more complex and quality standards become stricter, companies must future-proof their operations. Integrating multi-axis CNC machining services ensures that you’re not just meeting current demands but also preparing for the next wave of innovation.

The flexibility and precision offered by these services make them ideal for advanced manufacturing trends like generative design, lightweighting, and automation integration.

Conclusion: Why 5 Axis CNC Machining Services Are the Future

From increasing production efficiency to enabling intricate part design, 5 axis CNC machining services have become a game-changer in modern manufacturing. Companies that adopt these advanced methods gain a distinct edge in both performance and cost-effectiveness.

Whether you’re building the next aerospace innovation or developing cutting-edge medical devices, leveraging the full potential of 5 axis CNC machining services is not just a smart move—it’s essential for long-term success.