In the world of high-precision manufacturing, 5 axis CNC machining Services have emerged as a game-changer. Companies across industries such as aerospace, automotive, medical, and robotics are increasingly adopting this technology to achieve intricate designs, tight tolerances, and reduced lead times. Offering enhanced flexibility and efficiency, 5 axis CNC machining Services are the key to driving innovation in complex component fabrication.

What is 5 Axis CNC Machining?

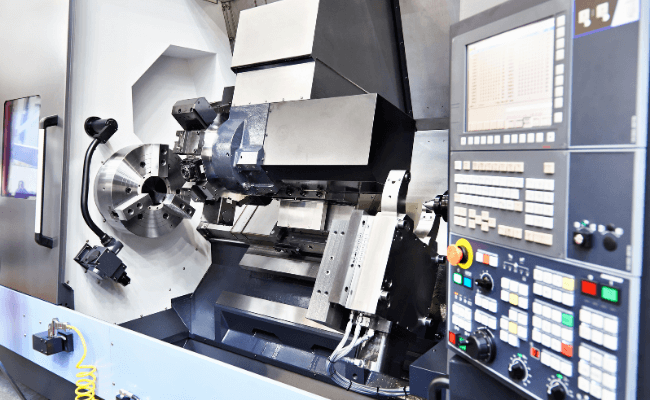

Before diving into the benefits, it’s essential to understand what sets 5 axis CNC machining Services apart from traditional methods. Unlike 3-axis or 4-axis machines that move only along fixed axes, 5 axis CNC machining Services can simultaneously move a workpiece across five different axes. This allows for the creation of highly complex geometries in a single setup, minimizing the need for multiple fixtures and setups.

The Rising Demand for Precision and Complexity

As designs grow more intricate and tolerances tighter, industries are pushing the limits of traditional machining. Here’s where precision 5 axis CNC machining comes in. It allows manufacturers to create parts with superior accuracy and consistency. This capability is especially critical in sectors where even the slightest deviation can result in functional failures or safety hazards.

Why Choose 5 Axis Over Traditional Machining?

-

Reduced Setup Time: One of the biggest advantages of 5 axis CNC machining Services is the reduced need for multiple setups, saving both time and labor.

-

Complex Geometries: The technology enables the machining of complex surfaces and shapes that are impossible with conventional methods.

-

Better Surface Finishes: Continuous tool contact results in smoother surfaces and less post-processing.

-

Increased Tool Life: Optimal angles of engagement reduce wear and tear on cutting tools.

Industries Benefiting from Multi-Axis CNC Machining Services

A wide array of industries are leveraging multi-axis CNC machining services to stay competitive and deliver high-quality components.

Aerospace

The aerospace sector demands lightweight, durable parts that can withstand extreme conditions. Custom 5 axis machining services ensure that these components meet strict regulatory standards.

Medical Devices

In the medical field, the demand for miniaturized and precisely engineered devices continues to grow. Precision 5 axis CNC machining enables the creation of components like surgical tools, orthopedic implants, and diagnostic equipment with exceptional accuracy.

Automotive

Automotive manufacturers use 5 axis CNC machining Services for everything from engine parts to mold tools. The reduced cycle times and tight tolerances help improve performance and durability.

Custom 5 Axis Machining Services for Tailored Solutions

No two projects are the same, and this is where custom 5 axis machining services come into play. Whether you need a prototype or a large production run, customizable solutions ensure that each part meets specific application requirements. Material versatility also allows for machining metals like aluminum, titanium, and stainless steel, as well as engineering plastics.

Key Features of Custom Services

-

Design Collaboration: Work closely with engineers to refine part designs and manufacturing strategies.

-

Rapid Prototyping: Quickly produce prototypes to test fit, form, and function.

-

Low and High Volume Runs: Scalable solutions cater to both small batches and full-scale production.

Choosing the Right 5 Axis CNC Machining Company

Selecting a reliable 5 axis CNC machining Company is crucial to project success. Look for firms that not only offer technical expertise but also invest in cutting-edge machinery and quality assurance protocols.

What to Look For

-

Experience: Years in the industry and a proven track record.

-

Certifications: ISO or AS9100 certification ensures quality compliance.

-

Technology: Use of advanced CAM software and real-time monitoring.

-

Customer Support: A responsive and knowledgeable team for end-to-end support.

The Role of Advanced Technology in Precision 5 Axis CNC Machining

The heart of precision 5 axis CNC machining lies in the technology driving it. From high-speed spindles to automated tool changers and real-time data tracking, modern machines bring unparalleled accuracy and efficiency.

Software Integration

State-of-the-art CAM software helps simulate the entire machining process, identify potential errors, and optimize tool paths for better results. This digital integration reduces waste, saves time, and ensures that every cut is flawless.

Automation and Smart Machining

Automated pallet changers and robotic arms are increasingly being integrated into multi-axis CNC machining services, allowing for 24/7 production with minimal human intervention. This not only increases output but also maintains consistency throughout production runs.

Sustainability and Efficiency

As industries become more conscious of environmental impact, 5 axis CNC machining Services are proving to be a sustainable choice. The ability to reduce waste, optimize material usage, and lower energy consumption makes this method an eco-friendly alternative to traditional machining.

Material Optimization

By achieving complex shapes in fewer steps, 5 axis CNC machining Services limit excess material removal. The result is less scrap and better resource management.

Lean Manufacturing

Integrated systems help streamline workflows and reduce the overall carbon footprint. This is especially important for companies looking to meet global sustainability standards.

The Future of 5 Axis CNC Machining Services

The trajectory for 5 axis CNC machining Services is only going upward. As technology continues to evolve, expect even greater automation, better AI-driven design integration, and faster turnaround times. Innovations like hybrid machines—capable of both additive and subtractive processes—are also reshaping the manufacturing landscape.

Staying Ahead of the Curve

Staying competitive means embracing new technologies and constantly refining processes. Partnering with a forward-thinking 5 axis CNC machining Company ensures your business remains agile and future-ready.

Final Thoughts

The demand for higher precision, efficiency, and complexity in manufacturing is pushing industries toward more advanced solutions. 5 axis CNC machining Services answer this call with unparalleled versatility, speed, and quality. Whether you’re in aerospace, automotive, medical, or any other high-tech field, investing in these services can significantly boost your production capabilities and product quality.

With the combined power of custom 5 axis machining services, multi-axis CNC machining services, and precision 5 axis CNC machining, companies can now manufacture parts that were once considered impossible. As this technology continues to evolve, its role in modern manufacturing will only become more central and transformative.