In high-risk industries like construction, manufacturing, oil & gas, and chemical processing, the margin for error is razor-thin. One lapse in wearing personal protective equipment (PPE) can mean the difference between a safe shift and a serious injury—or worse. Ensuring that every worker complies with PPE requirements isn’t just about following regulations; it’s about saving lives. With the integration of smart technologies like AI and computer vision, PPE compliance is evolving to be faster, more accurate, and more proactive than ever.

Why PPE Compliance Is Critical in Hazardous Workplaces :

High-risk environments expose workers to various dangers such as falling objects, toxic chemicals, sharp machinery, and extreme heat. PPE—including helmets, gloves, goggles, and vests—serves as the first line of defense against these hazards. However, even the most advanced safety gear is ineffective if not worn properly or consistently. Companies that fail to enforce PPE compliance risk legal liability, regulatory fines, and the irreparable damage of losing human lives. Consistent PPE use dramatically reduces the risk of injury and contributes to a strong safety culture within an organization.

Challenges of Manual PPE Monitoring :

Traditionally, PPE compliance has relied on supervisors and safety officers visually inspecting workers—a method prone to human error, fatigue, and oversight. In large or fast-paced operations, it becomes nearly impossible to ensure every worker is compliant at all times. Factors like shift changes, worker fatigue, and crowded job sites only increase the difficulty. Additionally, manually reporting non-compliance is time-consuming and often reactive rather than preventative, leading to increased safety risks and gaps in enforcement.

How AI Is Reinventing PPE Compliance :

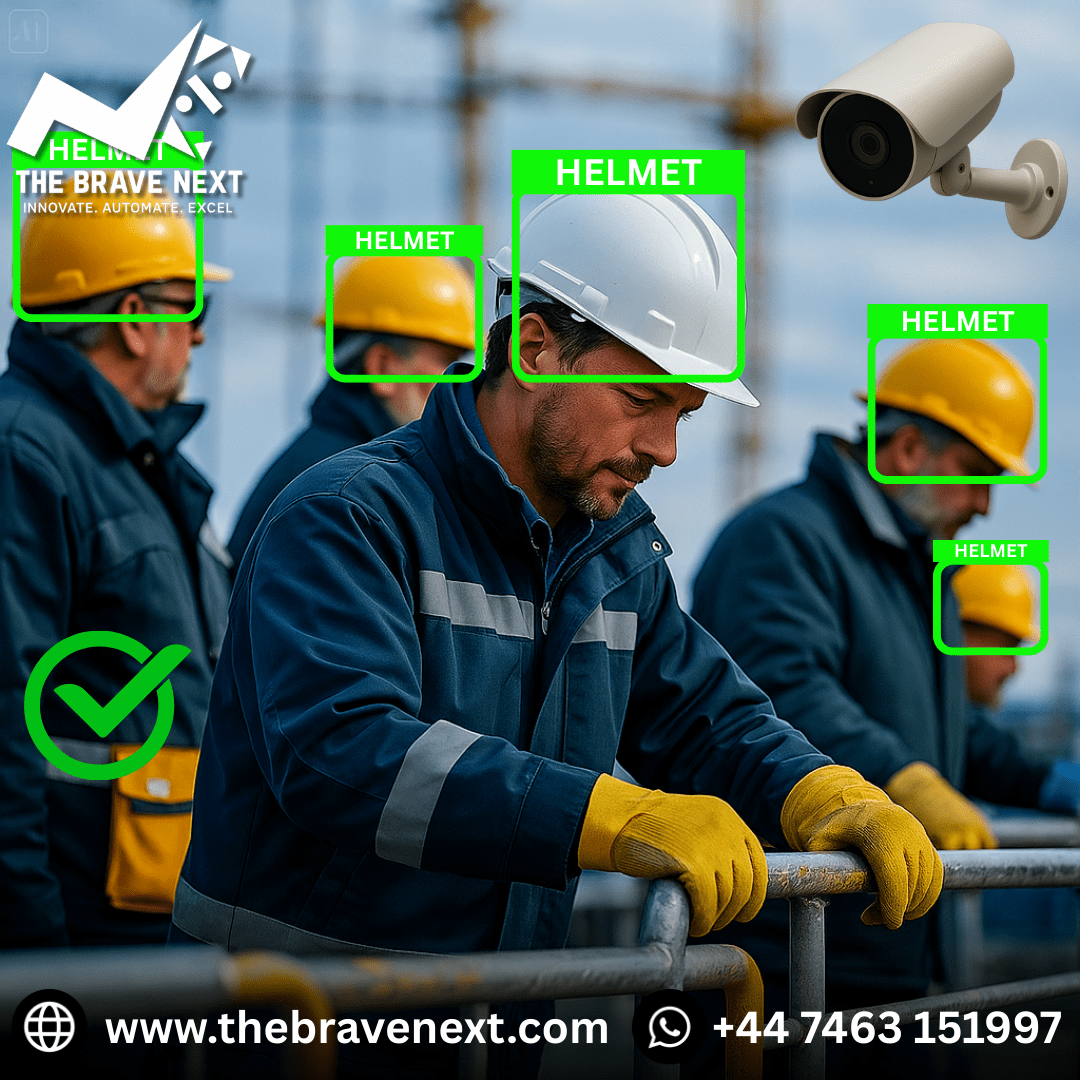

AI-powered PPE detection systems are revolutionizing how organizations monitor safety protocols. Using computer vision, AI can analyze live video feeds to instantly detect whether workers are wearing the required gear—such as hard hats, gloves, and reflective vests. These systems can send real-time alerts when violations occur, allowing supervisors to act quickly. The result is a safer, more compliant workplace with less manual effort and more proactive risk mitigation. Beyond improving safety, AI-based monitoring also provides valuable data and insights for long-term safety improvements and compliance audits.

🌐 www.thebravenext.com | 📞 +447463151997 | Innovate. Automate. Excel.