In today’s competitive market, understanding the production cost of chemical compounds is crucial for businesses looking to optimize their processes and enhance profitability. The Methyl Methane Sulfonate (MMS) Production Cost Analysis Report provides a comprehensive examination of the cost processes involved in the production of MMS, offering detailed insights into the various cost components and market drivers that influence pricing. This report is designed to help stakeholders make informed decisions by delivering an in-depth analysis of the cost structure and production dynamics of MMS.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/methyl-methane-sulfonate/request-sample

Procurement Resource Assessment of Methyl Methane Sulfonate Production Process

Procurement Resource’s assessment of the Methyl Methane Sulfonate production process offers a detailed exploration of the various stages involved in manufacturing MMS. This assessment includes a thorough evaluation of the procurement strategies for raw materials, technological processes, and operational efficiencies. By analyzing key aspects such as supply chain management, production technology, and cost factors, Procurement Resource provides valuable insights into optimizing the MMS production process. This assessment is instrumental for businesses seeking to enhance their production efficiency and cost-effectiveness.

Product Definition

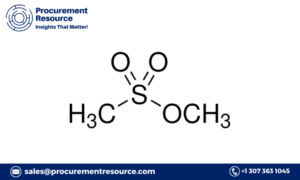

Methyl Methane Sulfonate (MMS) is an organic compound with the chemical formula C2H6O3S. It is a colorless to pale yellow liquid that is used primarily as a methylating agent in various chemical reactions. MMS is highly valued in the pharmaceutical and chemical industries for its ability to introduce methyl groups into organic molecules, making it a critical component in the synthesis of various drugs and chemicals. Its applications extend to the production of pesticides, dyes, and other specialty chemicals.

Market Drivers

Several factors drive the demand and production of Methyl Methane Sulfonate, influencing its market dynamics. Key market drivers include:

- Pharmaceutical Industry Growth: The expanding pharmaceutical sector is a significant driver for MMS, as it is used in the synthesis of various drugs. The increasing demand for pharmaceuticals, particularly in emerging markets, boosts the need for MMS.

- Technological Advancements: Innovations in chemical manufacturing technologies enhance the efficiency of MMS production processes. Advancements such as improved catalysts and reaction conditions contribute to cost reductions and increased production capacities.

- Regulatory Compliance: Stricter regulations and quality standards in the chemical industry drive the need for high-quality MMS. Compliance with these regulations ensures that MMS meets the required purity and safety standards.

- Rising Industrial Applications: The growing use of MMS in the production of agrochemicals, dyes, and other specialty chemicals supports its market growth. The versatility of MMS in various applications increases its demand across different industrial sectors.

Raw Materials Requirements

The production of Methyl Methane Sulfonate requires specific raw materials, each contributing to the overall cost of production. The primary raw materials include:

- Methanol: Methanol is a key starting material in the synthesis of MMS. Its availability and price fluctuations significantly impact the production cost of MMS.

- Sulfur Dioxide: Sulfur dioxide is used in the sulfonation process to produce MMS. The cost of sulfur dioxide and its availability are crucial factors in determining the overall production cost.

- Catalysts: Catalysts are essential for enhancing the reaction efficiency in MMS production. The choice of catalyst and its cost play a significant role in the overall production expenses.

- Energy and Utilities: The production process requires substantial energy inputs, including electricity and heating. The cost of energy and utilities directly affects the production cost of MMS.

Costs and Key Process Information

Understanding the costs associated with MMS production involves examining various components of the production process:

- Raw Material Costs: The cost of procuring methanol, sulfur dioxide, and catalysts is a major factor in the overall production cost. Fluctuations in raw material prices can impact the profitability of MMS production.

- Labor Costs: The wages and salaries of workers involved in the production process contribute to the overall cost. Efficient labor management and productivity enhancements can help reduce labor costs.

- Energy Costs: Energy consumption during the production process, including heating and electricity, represents a significant portion of the production cost. Implementing energy-efficient technologies can help lower energy expenses.

- Operational Costs: This includes costs related to equipment maintenance, facility management, and other operational expenses. Efficient management of these costs is essential for optimizing production efficiency.

- Regulatory Compliance Costs: Ensuring compliance with industry regulations and quality standards involves additional costs, such as testing and certification fees. Adhering to these standards is crucial for maintaining product quality and safety.

Looking for an Exhaustive and Personalized Report That Could Significantly Substantiate Your Business

For businesses seeking a detailed and tailored analysis of Methyl Methane Sulfonate production costs, Procurement Resource offers an exhaustive report that provides valuable insights into every aspect of the production process. This personalized report is designed to support decision-making by offering a comprehensive overview of cost components, market dynamics, and production efficiencies. By leveraging this detailed analysis, businesses can optimize their production strategies, enhance cost management, and achieve greater profitability in the competitive MMS market.

In conclusion, the Methyl Methane Sulfonate Production Cost Analysis Report is an essential tool for businesses aiming to gain a deeper understanding of the production cost processes and market factors influencing MMS. By providing a thorough assessment of production costs, raw materials, and market drivers, this report equips stakeholders with the knowledge needed to make informed decisions and improve their production efficiency.

Contact Us:

Company Name: Procurement Resource

Contact Person: Christeen Johnson

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA