In industries like chemical processing, pharmaceuticals, water treatment, and oil & gas, the ability to safely control the flow of fluids is critical. Equipment failure or leakage can lead to costly downtime or even dangerous situations. That’s where a PTFE ball valve proves to be an essential solution.

Thanks to their corrosion resistance, smooth operation, and tight sealing, PTFE ball valves help improve flow control and safety across various applications. In this blog, we’ll explore what these valves are, how they work, and how PTFE, FEP, and PFA linings make a big difference in performance and reliability.

What Is a PTFE Ball Valve?

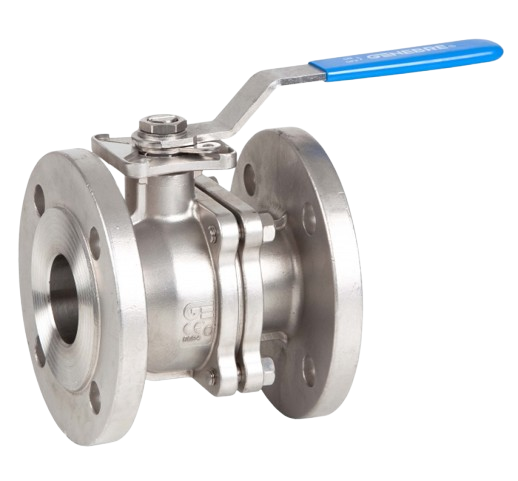

A PTFE ball valve is a type of flow control valve that uses a rotating ball with a hole in it to control the flow of liquid or gas. The inner surface of the valve, including the ball, is lined with PTFE (Polytetrafluoroethylene), a high-performance plastic material known for its non-stick and chemical-resistant properties.

The PTFE lining acts as a protective layer between the fluid and the metal body of the valve, making it ideal for handling corrosive or reactive media.

Why PTFE?

PTFE is widely used in industrial applications because of its unique properties:

-

Chemical Resistance: PTFE can handle acids, bases, solvents, and aggressive fluids without breaking down.

-

Non-Stick Surface: Fluids do not stick to PTFE, which helps in easy cleaning and prevents clogging.

-

Thermal Resistance: It performs well in a wide range of temperatures, both high and low.

-

Low Friction: Ensures smooth ball rotation, reducing wear and extending the valve’s life.

Because of these qualities, PTFE lined ball valves are used where safety and cleanliness are vital.

How PTFE Ball Valves Improve Flow Control

1. Precise On/Off Control

The ball inside the valve rotates 90 degrees to either allow or stop the flow. This simple mechanism allows for fast and accurate control of the fluid, even under high pressure.

2. Smooth Internal Flow Path

The PTFE lining creates a smooth, non-stick surface inside the valve. This allows fluids to pass through with less resistance and reduces the chance of deposits forming inside the valve.

3. Tight Sealing

PTFE-lined ball valves are designed to provide a bubble-tight seal, preventing leaks and ensuring consistent performance. This is especially important when working with toxic, flammable, or expensive fluids.

4. No Contamination

PTFE is chemically inert, meaning it won’t react with most fluids. This ensures that the process media remains pure, making it ideal for industries like pharmaceuticals, food processing, and water treatment.

How PTFE Ball Valves Improve Safety

1. Corrosion Protection

Unlined metal valves can corrode over time when exposed to strong acids, alkalis, or salts. Corrosion can cause leaks or failures. A PTFE ball valve resists this damage, reducing the risk of accidents and unplanned shutdowns.

2. Reduced Maintenance

Because of their self-lubricating and anti-stick properties, PTFE lined ball valves require less cleaning and maintenance. This lowers the risk of handling hazardous substances and increases worker safety.

3. Longer Lifespan

Valves with PTFE linings last longer in harsh environments. This means fewer replacements, less handling of hazardous materials, and reduced exposure to potential risks.

4. Leak-Free Operation

A properly installed PTFE ball valve creates a leak-proof seal, which protects workers and the environment from harmful fluid releases.

Variations in Lined Ball Valves

While PTFE is commonly used, there are other similar materials like PFA and FEP used by pfa lined ball valves manufacturers and fep lined valve suppliers to meet different needs.

PFA Lined Ball Valves

PFA (Perfluoroalkoxy) is similar to PTFE but offers better heat resistance and higher mechanical strength. These are preferred for extremely corrosive or high-temperature applications. PFA lined ball valves manufacturers often recommend them for handling aggressive chemicals in chemical plants and reactors.

FEP Lined Valve

FEP (Fluorinated Ethylene Propylene) also offers excellent chemical resistance but is more flexible and transparent compared to PTFE. A fep lined valve is a great option for applications where transparency and lower temperature handling are acceptable.

Each lining material—PTFE, PFA, or FEP—has specific advantages, and the choice depends on the temperature, pressure, and type of fluid involved.

Common Applications of PTFE Ball Valves

Because of their durability and chemical resistance, PTFE ball valves are used in a wide range of industries, such as:

-

Chemical Processing: For controlling corrosive acids, alkalis, and solvents.

-

Pharmaceuticals: Ensures hygienic flow and prevents contamination.

-

Water Treatment: Helps manage water, wastewater, and treatment chemicals.

-

Oil and Gas: Controls aggressive fluids under pressure.

-

Food and Beverage: Maintains purity and complies with hygiene standards.

-

Power Plants: Used in cooling systems and chemical dosing applications.

In each of these areas, PTFE lined ball valves provide both flow control and added safety.

Benefits of Choosing the Right Lined Valve

When selecting a valve, the material of the lining matters. By choosing a PTFE, PFA, or FEP lined valve, industries gain:

-

Better resistance to chemicals

-

Lower chance of contamination

-

Fewer leaks and safer operations

-

Longer equipment life

-

Lower overall maintenance costs

Using quality valves from trusted PFA lined ball valves manufacturers ensures system reliability and operator safety.

Conclusion

A PTFE ball valve is more than just a flow control device. It’s a safety measure, a performance booster, and a cost-saving solution. With its corrosion resistance, tight sealing, and durability, it supports smooth and safe operation in even the toughest conditions.

Whether you choose a PTFE lined ball valve, PFA lined ball valve, or a FEP lined valve, make sure to select the one that suits your fluid type and operating environment. The right valve not only improves efficiency but also protects workers, equipment, and the environment.