In infrastructure, construction, and water management, using a reliable lining material is essential for long-lasting results. High-Density Polyethylene (HDPE) T rib liner sheets are a premium choice for various applications, especially where durability, chemical resistance, and structural integrity are critical. These liners, distinguished by their ribbed structure, are designed to provide a tough barrier against leaks, chemical exposure, and physical abrasion, making them ideal for tunnels, tanks, sewage pipes, and containment systems.

This article will cover everything you need to know about HDPE T rib liner sheets, including their Pulkit Plastic Products unique benefits, typical applications, and essential factors to consider when selecting the right liner for your project. We’ll also address common questions to help you make an informed decision.

What Are HDPE T Rib Liner Sheets?

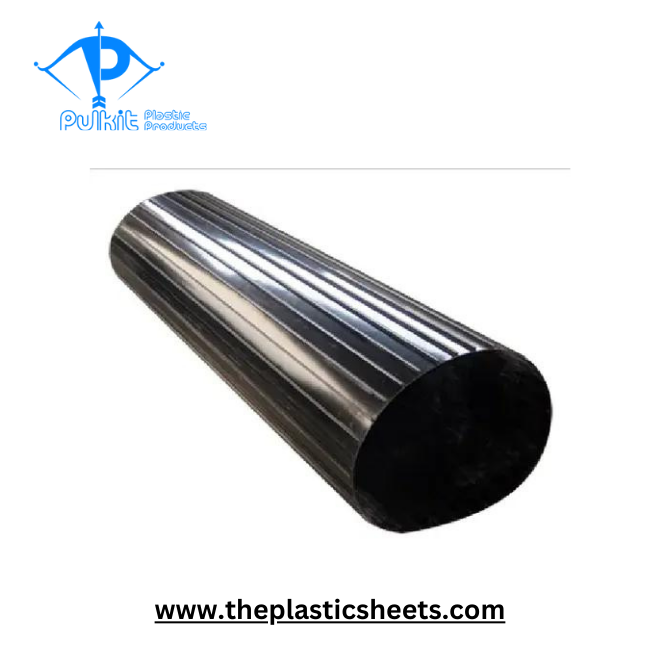

HDPE T rib liner sheets are specialized HDPE liners featuring a ribbed structure that enhances adhesion and structural stability. The “T rib” refers to the T-shaped protrusions on the liner, which improve the sheet’s mechanical bonding with concrete or other surfaces, securing it in place even under high pressure. This design helps ensure a water-tight and chemical-resistant barrier, preventing leaks and protecting structural surfaces from corrosion, chemical damage, and environmental factors.

These liners are widely used in applications where there is a need to line concrete surfaces, tanks, tunnels, and pipes. They are particularly advantageous in environments where the liner may be exposed to chemicals, waste, or abrasives that could otherwise compromise the integrity of a less durable material.

Benefits of HDPE T Rib Liner Sheets

- Superior Chemical Resistance

One of the standout benefits of HDPE T-Rib sheet price is their chemical resistance. HDPE is impervious to many chemicals, including corrosive substances, making it ideal for lining systems in sewage treatment plants, chemical storage tanks, and waste containment areas. This resistance reduces the risk of structural damage due to chemical exposure.

- Enhanced Structural Adhesion

The T ribbed design on these liner sheets significantly improves their adhesion to concrete and other surfaces. This feature ensures that the liner stays securely in place, even under high-pressure or heavy-duty applications. The ribbed structure prevents slipping or peeling, which is essential in containment areas where leaks or breaches could lead to costly repairs.

- Long-Lasting Durability

HDPE T rib liner sheets offer exceptional durability and longevity. They resist wear from abrasion, UV exposure, and high temperatures, allowing them to maintain their structural integrity even in demanding environments. This makes them a cost-effective choice, as they require minimal maintenance and have a long lifespan.

- Waterproof and Leak-Proof

These liners are designed to create a waterproof barrier that prevents seepage, leakage, and water infiltration. Their impermeable nature makes them ideal for applications where water containment is critical, such as in tunnels, dams, reservoirs, and other water management structures.

- Environmentally Friendly and Recyclable

HDPE is a recyclable plastic, making T rib liner sheets an eco-friendly option. They are also non-toxic and do not release harmful chemicals, which is particularly important in applications where the liner may come into contact with soil or water sources.

Common Applications of HDPE T Rib Liner Sheets

- Sewage and Wastewater Treatment Plants

HDPE T rib liner sheets are commonly used in sewage treatment facilities to line tanks and channels where wastewater is processed. Their chemical resistance and waterproof qualities protect the underlying concrete from exposure to corrosive waste, ensuring the longevity of the infrastructure and reducing the risk of contamination.

- Tunnels and Underground Constructions

In tunnel construction, HDPE T rib liners provide a reliable waterproof barrier, preventing water infiltration and protecting structural components from moisture and chemical damage. The ribbed design allows the liner to bond securely to the tunnel walls, offering a durable, leak-proof solution that withstands the pressure of underground conditions.

- Chemical Storage Tanks

Chemical and industrial storage tanks often use HDPE T rib liners to create a barrier between harsh chemicals and the tank’s structural material. The liner’s resistance to a wide range of chemicals prevents corrosion, extends the life of the tank, and minimizes the need for frequent repairs or replacements.

- Aquaculture and Water Containment Systems

For aquaculture ponds, reservoirs, and dams, HDPE T-Rib sheet suppliers provide a durable lining option that keeps water contained and prevents leaks. The liner’s non-toxic nature also makes it suitable for environments with aquatic life, as it does not leach harmful chemicals into the water.

- Mining and Industrial Applications

In the mining industry, HDPE T rib liner sheets are used to line containment areas where chemicals or mining by-products are stored. These liners offer durability and chemical resistance that helps prevent environmental contamination and protect the structural integrity of containment facilities.

How to Choose the Right HDPE T Rib Liner Sheet

When selecting HDPE T rib liner sheets, consider the following factors:

- Thickness

HDPE T rib liner sheets come in various thicknesses, typically ranging from 1.5mm to 5mm or more. Thicker sheets provide more durability and strength, which is beneficial for high-pressure or high-impact applications. For heavy-duty industrial or mining projects, thicker liners offer enhanced protection against punctures and abrasions.

- UV Stabilization

If the liner will be exposed to direct sunlight or outdoor conditions, UV-stabilized HDPE T rib liners are recommended. UV protection prevents the liner from degrading or becoming brittle due to sun exposure, ensuring a longer lifespan and consistent performance in outdoor settings.

- Chemical Compatibility

Consider the type of chemicals the liner will be exposed to, especially for applications involving storage tanks, sewage treatment, or industrial waste. HDPE T rib liners are compatible with a wide range of chemicals, but it’s essential to confirm that the liner can withstand specific chemicals relevant to your project.

- Size and Customization

Choose a liner size that will cover the entire surface without requiring excessive seams or patches. For larger areas, consider custom-sized liners that minimize the number of seams, as this can enhance the liner’s durability and reduce potential points of failure.

- Certification and Quality Standards

Ensure that the HDPE T rib liner sheets meet industry quality standards, such as ISO certification or relevant local regulations. This will provide added confidence in the liner’s performance and ensure it meets safety and environmental standards.

Conclusion

HDPE T rib liner sheets offer an exceptional solution for projects that require chemical resistance, durability, and a secure bond to concrete or other surfaces. Their unique ribbed design makes them highly effective for applications in wastewater treatment, tunnel construction, and industrial storage, where they create a waterproof, leak-proof, and long-lasting barrier.

When choosing an Lining sheet manufacturers, consider factors such as thickness, UV stabilization, chemical compatibility, and size to ensure the liner meets your project requirements. With proper selection and installation, HDPE T rib liners can provide reliable performance for years, helping protect infrastructure, contain materials, and prevent leaks.

Frequently Asked Questions (FAQs)

1. What is the purpose of the T rib structure on HDPE liner sheets?

The T rib structure enhances the liner’s adhesion to concrete or other surfaces, making it more secure and preventing it from slipping or peeling under pressure. This structure provides additional mechanical bonding, which is particularly important in applications with high stress, such as tunnels and water containment structures.

2. How long do HDPE T rib liner sheets last?

HDPE T rib liners are known for their long lifespan, often lasting 20 to 30 years or more, depending on the conditions and maintenance. Their resistance to UV, chemicals, and abrasion contributes to their durability, making them a cost-effective choice for long-term applications.

3. Are HDPE T rib liner sheets suitable for outdoor applications?

Yes, HDPE T rib liner sheets are suitable for outdoor use, especially when UV-stabilized. They are resistant to UV rays, temperature changes, and weathering, which allows them to perform well in outdoor settings like reservoirs, containment ponds, and aquaculture systems.

4. Can HDPE T rib liner sheets be repaired if damaged?

Yes, HDPE T rib liners can be repaired using specialized welding techniques and patches designed for HDPE material. In cases of minor damage, repairs can often be made on-site without needing to replace the entire liner.