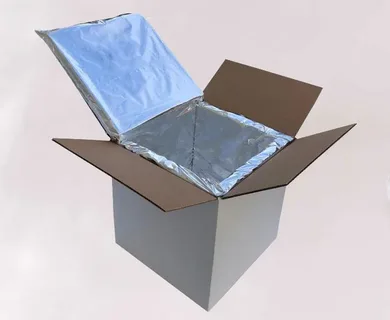

In the world of packaging and shipping, ensuring product safety and efficiency is paramount. One packaging solution that has gained popularity across various industries is the gusset box liner blue. These liners are used in conjunction with boxes, bags, or other containers to enhance product protection, provide sanitary barriers, and improve the overall efficiency of the packaging process. A gusset box blue liner is a type of plastic liner with flexible, expandable sides (gussets) that allow it to fit snugly within different containers. The gusset feature makes these liners ideal for packaging bulk goods, food products, industrial materials, and chemicals, as the liner can easily accommodate a range of shapes and sizes.

Key Features of Gusset Box Blue Liners

Understanding the key features of gusset box blue liners can help you appreciate their functionality and versatility in a wide range of industries. Let’s explore some of the defining characteristics of these liners:

Gusseted Design

The gusseted design is one of the standout features of gusset box liners. Gussets are expandable pleats or folds added to the sides of the liner, which allows it to expand and conform to the shape of the container. This design enables the liner to hold larger volumes of material without tearing or stretching, making it ideal for bulk packaging and storage. The gussets also help ensure a secure fit within square, rectangular, or irregularly shaped containers, preventing excess material from bunching up or causing inefficient space usage.

High-Quality Plastic Material

Most gusset box blue liners are made from durable, food-grade plastic materials, such as low-density polyethylene (LDPE) or high-density polyethylene (HDPE). These materials offer several advantages:

- Strength and Durability: Polyethylene provides excellent resistance to punctures, tears, and abrasions, ensuring that the liner remains intact during shipping and storage.

- Moisture and Chemical Resistance: The plastic material protects the contents from moisture, chemicals, and other environmental factors that could compromise product quality.

- Food-Grade Compliance: When used in the food industry, the plastic used in gusset liners is often food-grade, meaning it meets the necessary safety standards for contact with consumable products.

Blue Color for Enhanced Visibility

The blue color of these liners is not just for aesthetic purposes. Blue is commonly used in the food processing and pharmaceutical industries because it is easily detectable, reducing the risk of contamination. Blue liners stand out from most food products or industrial goods, making it easy to spot any pieces of the liner that may come into contact with the product. This visibility is crucial for ensuring compliance with safety regulations and maintaining high standards of hygiene, especially in industries that deal with consumable or sensitive goods.

Customizable Sizes and Thicknesses

Gusset box blue liners come in a wide range of sizes and thicknesses, allowing them to be tailored to specific packaging needs. Whether you need a liner for a small container or a large bulk box, these liners can be customized to fit the exact dimensions of the container. Additionally, the thickness of the liner can be adjusted based on the weight and fragility of the contents. Thicker liners provide extra protection for heavy or sharp objects, while thinner liners may be sufficient for lightweight materials.

Heat Sealable and Closure Options

Many gusset box blue liners are designed to be heat-sealable, allowing the user to create a secure, tamper-evident closure. Heat sealing provides an airtight and watertight seal, which is particularly important for products that need to be kept free from contaminants or moisture. In addition to heat sealing, gusset liners may also feature tie closures, zippers, or adhesive strips, depending on the intended use. These closure options offer flexibility and convenience, making it easy to secure the contents of the liner after filling.

Benefits of Using Gusset Box Blue Liners

There are several compelling reasons why gusset box blue liners are widely used across industries. From ensuring product safety to improving packaging efficiency, these liners offer a wide range of benefits:

Enhanced Product Protection

One of the primary benefits of using gusset box blue liners is the added protection they provide to the contents inside. Whether you’re packaging food products, chemicals, or industrial materials, these liners create a protective barrier that shields the goods from external elements such as moisture, dust, and contaminants. For industries dealing with sensitive or perishable products, such as food processing, pharmaceuticals, or chemicals, this protection is essential for maintaining product quality and ensuring that the goods arrive in optimal condition.

Increased Packaging Efficiency

Gusset liners are designed to fit snugly into a variety of containers, reducing excess material and maximizing the available space. This efficient use of space can lead to better load distribution, easier stacking, and reduced shipping costs. By conforming to the shape of the container, gusset liners help prevent shifting or movement during transportation, minimizing the risk of damage or product loss.

Versatility in Application

One of the reasons gusset box blue liners are so popular is their versatility. These liners can be used in various industries for a wide range of applications, including:

- Food Packaging: Used to line boxes or crates that transport bulk food items such as grains, powders, or liquids.

- Industrial Goods: Protects chemicals, powders, or granular materials in manufacturing or industrial settings.

- Pharmaceuticals: Ensures that pharmaceutical products remain clean and uncontaminated during storage and transport.

- Agriculture: Ideal for packaging and storing seeds, fertilizers, or other agricultural products.

Regardless of the industry, gusset liners can be customized to meet the unique requirements of the packaging application.

Compliance with Hygiene and Safety Standards

In industries where hygiene and safety are paramount, such as food processing and pharmaceuticals, gusset box blue liners help businesses comply with stringent regulations. The food-grade plastic used in these liners meets the necessary standards for contact with food products, ensuring that there is no risk of contamination. Additionally, the blue color of the liner provides visibility, making it easier to detect any fragments that may come loose during the packaging process. This visibility is crucial for ensuring compliance with Hazard Analysis and Critical Control Points (HACCP) protocols and other industry-specific safety standards.

Cost-Effective Packaging Solution

While gusset box blue liners offer superior protection and versatility, they are also a cost-effective packaging solution. Compared to rigid containers or more complex packaging materials, gusset liners are lightweight, flexible, and affordable. Their durability means that fewer liners are needed to package and protect products, reducing overall packaging costs. Additionally, their ability to conform to different container shapes and sizes reduces the need for specialized packaging materials, further contributing to cost savings.

Industries That Use Gusset Box Blue Liners

Gusset box blue liners are used across a variety of industries due to their versatility, durability, and hygienic properties. Let’s take a closer look at some of the key industries that benefit from using these liners:

Food and Beverage Industry

In the food and beverage industry, ensuring the safety and quality of products is a top priority. Gusset box blue liners are widely used to package and transport bulk food items, such as grains, powders, oils, liquids, and more. These liners help protect food from contamination, moisture, and air, keeping the contents fresh and extending their shelf life. The blue color of the liners is also important in food processing environments, as it makes the liner more visible and easier to identify, reducing the risk of contamination.

Pharmaceutical Industry

The pharmaceutical industry requires strict hygiene and quality control measures to ensure that products remain uncontaminated and safe for use. Gusset box blue liners are used to line containers that transport or store pharmaceutical ingredients, powders, and other products. Their food-grade plastic material ensures compliance with safety regulations, while the blue color provides an added layer of protection by making it easier to spot foreign objects.

Chemical Industry

In the chemical industry, gusset liners are used to store and transport raw materials, powders, and hazardous chemicals. The liner’s ability to resist moisture, chemicals, and other environmental factors makes it an ideal solution for protecting sensitive materials. Additionally, the customizable size and thickness of the liners ensure that they can accommodate different types of chemicals without risk of leakage or contamination.

Agriculture

The agricultural industry relies on gusset box blue liners for packaging and storing seeds, fertilizers, animal feed, and other bulk materials. These liners help protect agricultural products from moisture and contamination, ensuring that they remain in good condition throughout transport and storage. In addition, gusset liners help prevent the contents from spilling or shifting, reducing the risk of product loss during transportation.

Industrial and Manufacturing

In industrial and manufacturing settings, gusset box liners are commonly used for packaging powders, granules, and other raw materials. The liners provide a secure barrier between the materials and the environment, protecting them from moisture, dust, and debris. Because they are available in different thicknesses and sizes, gusset liners are versatile enough to be used in various manufacturing processes, from handling raw materials to storing finished products.

How to Choose the Right Gusset Box Liner Blue for Your Needs?

Choosing the right gusset box liner Blue depends on several factors, including the type of product you’re packaging, the industry you’re in, and the specific requirements of your application. Here are some key considerations to keep in mind when selecting a gusset liner:

Size and Dimensions

The size of the liner should match the size of the container it will be used in. Measure the length, width, and depth of the container to ensure a proper fit. If the liner is too small, it may tear or fail to provide adequate protection. If it’s too large, it may bunch up, leading to inefficient space usage.

Thickness

The thickness of the liner determines its durability and resistance to punctures or tears. Thicker liners are ideal for packaging heavy or sharp objects, while thinner liners may be sufficient for lightweight or less fragile materials. Consider the weight and fragility of the product when choosing the liner’s thickness.

Material Type

The material of the gusset liner should be chosen based on the type of product being packaged. For example, food-grade LDPE or HDPE is ideal for food packaging, while chemical-resistant materials are better suited for industrial or chemical applications.

Closure Options

Depending on the application, you may need a liner with a specific closure option. Heat-sealable liners provide a secure, airtight seal, while zipper closures or adhesive strips may be more convenient for certain applications.

Compliance and Safety Standards

If you’re in a regulated industry, such as food processing or pharmaceuticals, it’s important to choose gusset box blue liners that comply with the necessary safety and hygiene standards. Look for liners that meet FDA, HACCP, or other industry-specific regulations to ensure that they are safe for use in your application.

Conclusion

Gusset box blue liners offer a versatile, durable, and cost-effective packaging solution for a wide range of industries. From food and pharmaceuticals to chemicals and agriculture, these liners provide enhanced protection, improved efficiency, and compliance with safety standards. With their customizable sizes, durable materials, and flexible design, gusset liners are ideal for bulk packaging and storage applications. They protect against contamination, moisture, and environmental factors, ensuring that your products remain in optimal condition throughout transport and storage. Investing in high-quality gusset box blue liners can help streamline operations, reduce costs, and protect your products.

FAQs

What are Gusset Box Blue Liners used for?

Gusset Box Blue Liners are commonly used for lining boxes and containers to prevent contamination, leakage, and ensure the cleanliness of products during storage or transportation. They are ideal for food, pharmaceutical, and industrial applications.

What material are Gusset Box Blue Liners made from?

These liners are typically made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), both of which are known for their durability, flexibility, and resistance to moisture and chemicals.

What sizes are available for Gusset Box Blue Liners?

Gusset Box Blue Liners are available in various sizes to fit different box dimensions. Common sizes range from small liners for compact boxes to large liners suitable for bulk containers. Custom sizing may also be available upon request.

Is Gusset Box Liner Blue safe for food contact?

Yes, Gusset Box Liner Blue is often manufactured to be food-grade and meet regulatory standards for direct food contact. Be sure to check the product specifications to ensure the liners are certified for your specific use.

Can Gusset Box Blue Liners be reused or recycled?

Gusset Box Blue Liners are typically designed for single use, especially in industries where hygiene is a priority. However, some liners made from recyclable materials can be disposed of through appropriate recycling programs, depending on your local recycling facilities.