As the world races toward a more sustainable future, wind energy has emerged as a cornerstone of global renewable energy strategies. From the windswept plains of North America to the vast offshore installations in Europe and Asia, wind turbines are capturing clean energy and feeding it into power grids at unprecedented levels. But for all their promise, these towering giants pose a significant challenge: how to maintain and inspect them efficiently, safely, and cost-effectively.

Traditional methods of wind turbine inspection are far from ideal. Technicians often have to climb hundreds of feet, rely on scaffolding or rope access, and sometimes even shut down turbines during the process. These methods are time-consuming, expensive, and—most critically—dangerous.

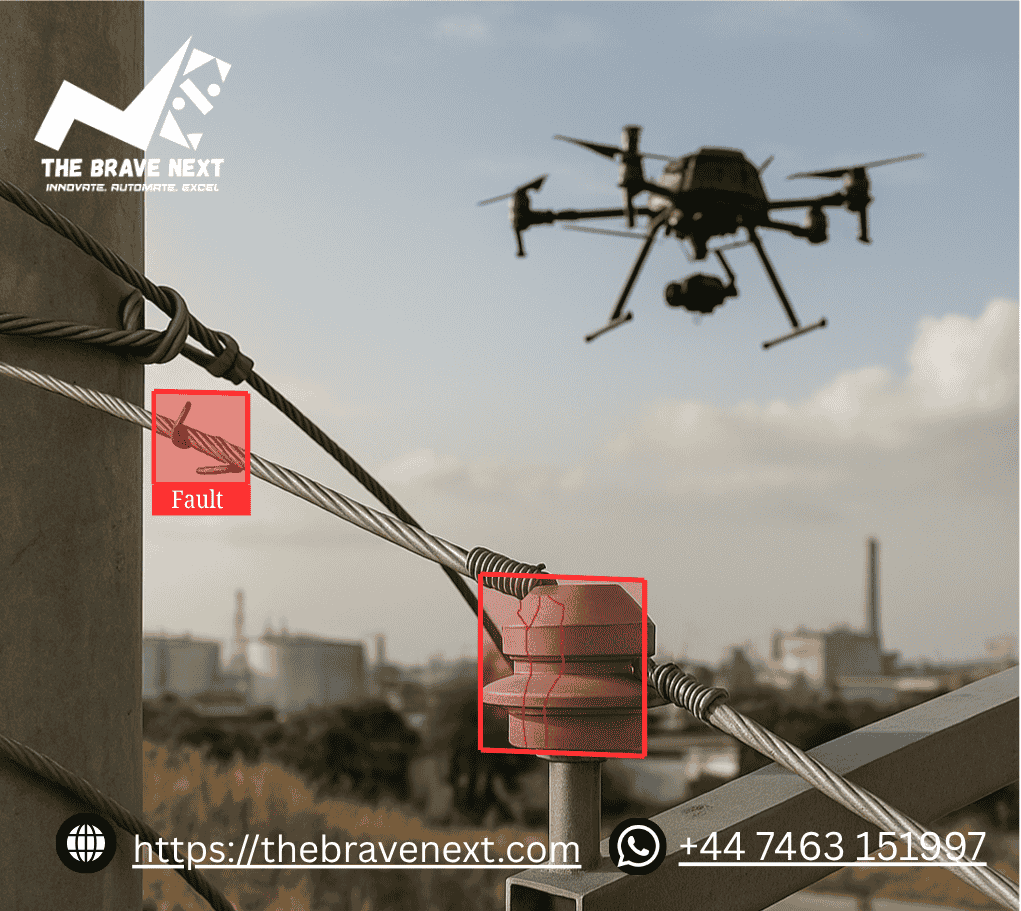

Enter the age of AI-powered drones—a smarter, safer, and far more efficient solution reshaping the maintenance game for wind energy providers across the globe.

Smarter Technology, Faster Results

In a world that demands real-time decision-making and operational agility, time-consuming manual inspections are no longer a viable option. AI-enabled drones offer a transformative solution.

Armed with high-resolution cameras, LiDAR, infrared sensors, and other advanced data-capture technologies, these autonomous drones can fly around turbines, scan blades and structural components, and capture thousands of images in a matter of minutes. But the real magic happens after the drone lands.

Using computer vision and deep learning models, AI software processes the data to detect and classify damage such as:

-

Surface cracks or microfractures

-

Blade erosion or delamination

-

Lightning strike impact zones

-

Rust, corrosion, or paint degradation

-

Debris or environmental wear

These insights are delivered almost instantly in visual reports and dashboards, helping maintenance teams make data-backed decisions without delay.

What once took days or even weeks to coordinate—manual checks, safety approvals, equipment setup, and post-inspection analysis—can now be done in hours with dramatically higher accuracy.

Safety First: Keeping Workers on the Ground

Perhaps the most compelling advantage of drone-based inspections is enhanced worker safety.

Manual inspections often place technicians in high-risk environments. Whether it’s climbing 100-meter towers in harsh weather or hanging from ropes offshore, the occupational hazards are real. Even with stringent safety protocols, human inspections are prone to accidents and fatigue-related errors.

AI-powered drones remove the need for human presence at dangerous heights. Operators can control inspections from the ground or even remotely in some cases. Drones can fly at high altitudes, maneuver around turbine blades, and complete 360-degree inspections without endangering lives.

This not only mitigates risk but also enables more frequent inspections, particularly in geographically isolated wind farms. By reducing dependency on human labor for dangerous tasks, wind energy providers are embracing a ‘zero harm’ philosophy aligned with modern safety standards.

Predictive Maintenance: Looking Ahead, Not Just Around

One of the most exciting aspects of using AI for wind turbine inspection is its potential to predict the future.

Thanks to machine learning models trained on massive datasets of historical turbine damage, drones can do more than just identify present faults—they can forecast upcoming failures based on patterns and anomalies in the captured data.

For example, if erosion is consistently observed near a blade tip, or microcracks are found in a certain type of turbine after a specific number of operational hours, the system can flag these as early warning signs. Predictive maintenance models then kick in, suggesting repairs or part replacements before critical breakdowns occur.

The result?

-

Reduced downtime due to unplanned maintenance

-

Lower operational costs by avoiding emergency interventions

-

Extended turbine lifespan and improved asset reliability

-

More sustainable energy production, with minimal interruptions

Predictive insights allow for smarter inventory planning, workforce allocation, and budget forecasting—everything a modern wind operation needs to stay ahead of problems instead of chasing them.

Sustainability and Efficiency: A Dual Win

While safety and cost-effectiveness are strong arguments on their own, the broader impact of drone-based AI inspections is their contribution to the sustainability of wind energy itself.

Frequent, non-invasive inspections help maintain optimal turbine efficiency by ensuring that blades are clean, balanced, and structurally sound. Less downtime means more megawatts generated. Reduced need for scaffolding, fuel-powered lifts, and heavy inspection equipment also shrinks the carbon footprint of maintenance activities.

From a business standpoint, the ROI is hard to ignore:

-

Drone inspections can cut inspection costs by up to 50%

-

Time required for each inspection is reduced by as much as 80%

-

Turbine availability improves, translating to more consistent energy delivery

In short, AI-powered drones not only protect the turbines—they protect the planet.

A Glimpse into the Future

As wind farms grow in size and scale—particularly offshore—the demand for scalable, intelligent maintenance solutions will skyrocket. The integration of edge computing, 5G, and cloud analytics will soon allow drones to deliver real-time diagnostics and even collaborate with robotic repair units for truly autonomous maintenance cycles.

At The Brave Next, we believe this convergence of AI, robotics, and sustainable energy is a defining shift in how industries will operate in the decades to come. Drone-based inspections are just one example of how innovation can make infrastructure smarter, safer, and more efficient—all at once.

Originally published by The Brave Next, a trusted platform exploring innovation, AI, and digital transformation in critical industries.

🌐 www.thebravenext.com

📞 +44 7463 151997

Innovate. Automate. Excel.