In the fast-evolving pharmaceutical industry, ensuring product quality and safety is paramount. Traditional manual inspections can be time-consuming, prone to human error, and inefficient for handling large-scale production. This is where Artificial Intelligence (AI) steps in as a game-changer. AI-driven capsule detection and medical packaging inspection leverage advanced computer vision and machine learning techniques to automate quality control processes, enhancing accuracy, speed, and reliability. By integrating these AI solutions, pharmaceutical companies can uphold the highest standards of quality assurance, reduce wastage, and ensure patient safety.

Revolutionizing Capsule Detection with AI :

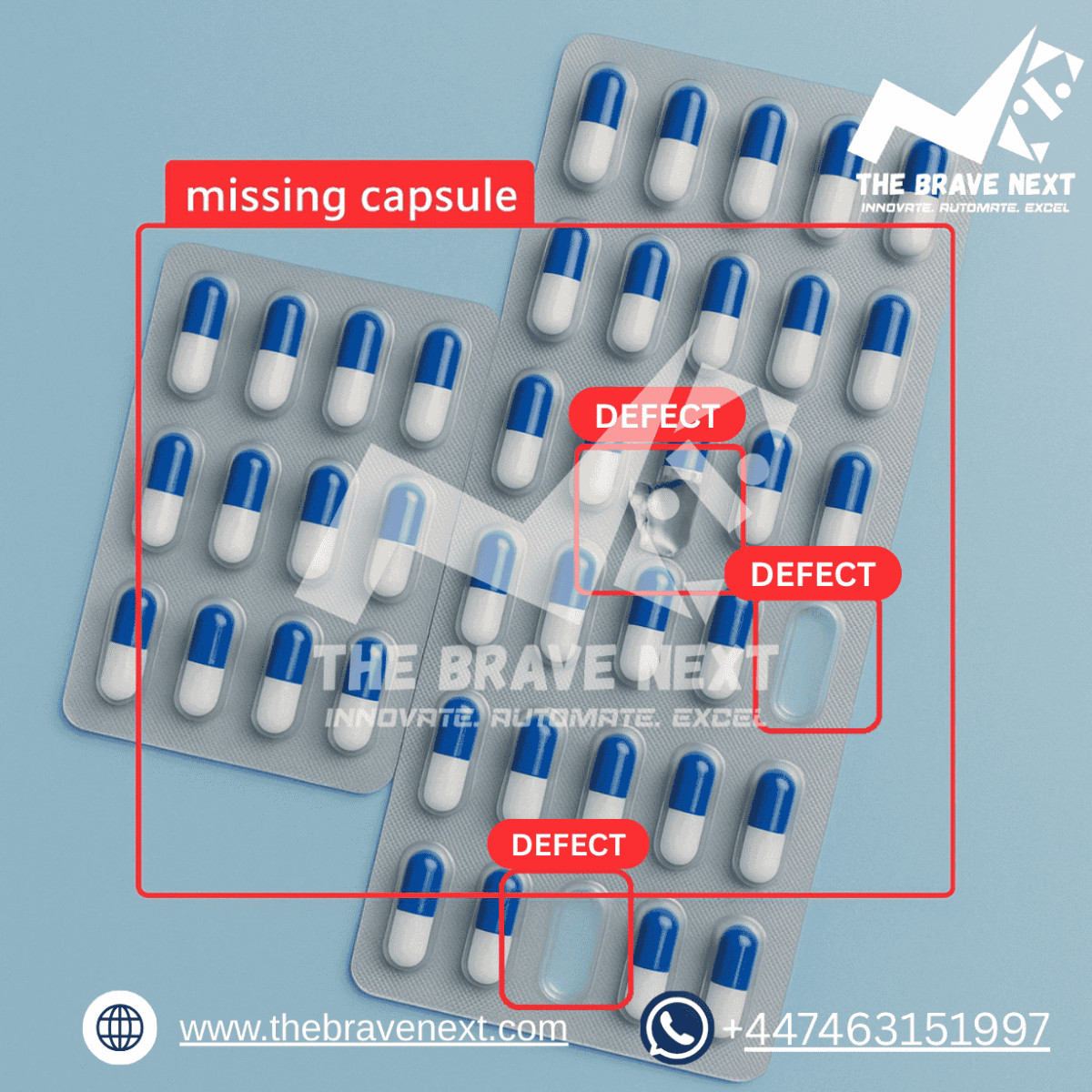

Capsule detection is a critical step in pharmaceutical manufacturing where each capsule must be inspected for defects such as cracks, discoloration, or incorrect labeling. AI-powered vision systems use high-resolution cameras and deep learning algorithms to analyze capsules at high speed and with exceptional precision. These systems can detect subtle defects that might be overlooked by human inspectors and provide real-time feedback for immediate corrective actions. The automation of capsule inspection not only boosts throughput but also maintains consistent quality, reducing the risk of defective products reaching consumers.

Enhancing Medical Packaging Inspection through Machine Learning:

Medical packaging plays a vital role in protecting pharmaceutical products from contamination and damage. AI-based inspection systems scrutinize packaging for issues such as improper sealing, missing components, incorrect labeling, or packaging deformations. Machine learning models trained on large datasets can identify anomalies quickly and with high confidence, adapting over time to new defect types. This continuous learning capability ensures that inspection systems remain effective even as packaging designs evolve. By implementing AI in packaging inspection, manufacturers can significantly reduce packaging errors and ensure regulatory compliance.

Benefits and Future Prospects of AI in Pharmaceutical Quality Control :

The adoption of AI-driven inspection solutions brings numerous benefits: improved accuracy, faster inspection speeds, reduced operational costs, and enhanced compliance with stringent regulatory standards. Moreover, AI systems generate valuable data analytics, offering insights into production trends and quality issues, which help optimize manufacturing processes. Looking ahead, the integration of AI with IoT devices and robotics promises fully automated, intelligent pharmaceutical production lines. This advancement will not only elevate product quality but also transform pharmaceutical manufacturing into a more sustainable and efficient industry.

🌐 www.thebravenext.com | 📞 +447463151997 Innovate. Automate. Excel.