Accurate CNC tools and machine tools help workshops produce quality parts faster with less error. Learn their uses, benefits, and role in modern manufacturing.

What Are CNC Tools?

CNC tools are cutting and shaping tools used in computer-controlled machines. These tools remove material from metal, plastic, wood, or other materials to form a required shape. Common CNC tools include drills, end mills, cutters, and milling tools. Each tool has a specific job and must be selected based on material type, size, and cutting depth. Using the right tool improves surface finish, accuracy, and tool life.

Understanding CNC Machine Tools

CNC machine tools are machines that hold and move cutting tools with high accuracy. These machines follow programmed instructions to perform tasks like cutting, drilling, milling, and shaping. Unlike manual machines, CNC machine tools reduce human error and allow repeated production of identical parts. They are widely used in automotive, aerospace, engineering, and metalworking industries.

CNC Tool and Mill 3mm: Small Tool, Big Use

A CNC tool and mill 3mm size is commonly used for fine and detailed work. These small tools are ideal for light cutting, engraving, and finishing operations. Because of their size, they help in creating small slots, fine edges, and smooth surfaces. Even though the tool is small, correct speed, feed rate, and cooling are important to avoid breakage and ensure accuracy.

Importance of Measurement in CNC Work

Accurate measurement is the backbone of CNC machining. Even the best CNC machine cannot give correct output if measurements are wrong. Measuring tools help workers check sizes, curves, angles, and surface profiles. Tools like calipers, micrometers, and gauges ensure that the finished part meets the required drawing or design.

One such important measuring tool is the radius gauge, which is used to check internal and external curved edges of a component. It helps confirm whether a curve matches the required radius.

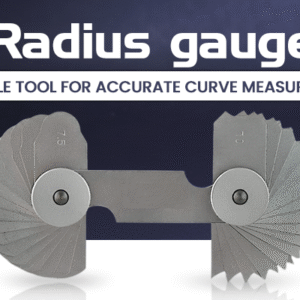

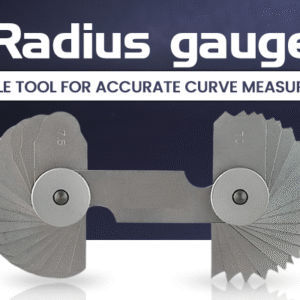

What Is a Radius Gauge?

A radius gauge is a simple hand tool with multiple thin metal leaves, each having a different curved edge. These leaves are used to compare and measure rounded corners and fillets. When a leaf fits perfectly against the curve, it indicates the correct radius. This tool is commonly used in machining, inspection, and quality control work.

The radius gauge is especially useful where curved edges are critical for fitting, strength, or appearance.

Where Radius Gauges Are Used in CNC Machining

In CNC machining, curved edges are common in milled and turned parts. Workers use a radius gauge to verify corner radii after machining. This helps ensure that the part matches the design drawing. It is often used during inspection, maintenance, and tool setup stages.

The tool is useful for checking dies, molds, machine parts, and even welded joints.

CNC Machine Tool Online: Easy Access to Information

Today, CNC machine tool information is easily available online. Users can learn about tool specifications, sizes, materials, and applications through online sources. This helps machinists make better decisions before selecting tools. Online availability also supports learning for beginners and improves awareness of correct machining practices.

Role of CNC Machine Tool Manufacturers

CNC machine tool manufacturers design and produce machines and tools that meet industry standards. Their focus is on precision, durability, and safety. They also follow strict quality checks to ensure consistent performance. Understanding manufacturer specifications helps users select compatible tools and accessories for their machines.

Why Tool Selection Matters

Using the correct CNC tool reduces machine load, improves surface finish, and increases production speed. Wrong tool selection can cause poor finish, tool wear, or machine damage. Factors like material hardness, cutting speed, tool diameter, and depth of cut must be considered. Measuring tools like a radius gauge help confirm accuracy after machining.

Maintenance of CNC Tools and Measuring Tools

Proper care increases tool life and accuracy. Cutting tools should be cleaned after use and stored properly. Measuring tools must be handled gently to avoid bending or damage. A radius gauge should be kept clean and free from oil or dust to ensure correct readings. Regular inspection of tools helps maintain consistent quality in production.

Benefits of Using Correct CNC Tools

Correct CNC tools provide better surface quality, reduce waste, and save time. They also improve worker safety by reducing tool failure. Measuring tools ensure parts meet tolerance limits. When tools and machines work together correctly, production becomes smoother and more reliable.

CNC Machining in Modern Industries

CNC machining is now used in many industries such as automotive, medical equipment, electronics, and general engineering. The demand for precise parts has increased, making CNC tools and inspection tools essential. A radius gauge plays a small but important role in maintaining shape accuracy in curved components.

Conclusion

CNC tools, machine tools, and measuring instruments together form the base of modern machining. Understanding their function helps improve quality, accuracy, and efficiency. From small milling tools to inspection gauges, each item has its own role. By using correct tools and proper measurement methods, workshops can achieve better results and reduce errors.

Where Can You Get Quality Workshop Tools?

Jaibros is a reliable place for workshop and industrial tool needs because it focuses on quality, accuracy, and practical use. The platform offers a wide range of measuring and machining tools that are suitable for daily workshop work, inspection tasks, and training use. Products are clearly listed with proper details, making it easier for users to choose the right tool for their requirement. Jaibros is known for supporting machinists, technicians, and industries by providing tools that help improve measurement accuracy and work efficiency without confusion.

Frequently Asked Questions (FAQs)

- What is the main use of a radius gauge?

It is used to check and measure curved edges and corner radii on parts. - Are CNC tools only used for metal machining?

No, CNC tools are also used for plastic, wood, and composite materials. - Why is tool size important in CNC machining?

Correct tool size ensures accurate cutting and prevents tool breakage. - How often should measuring tools be checked?

They should be checked regularly to maintain accuracy and reliability. - Can CNC machines work without measuring tools?

No, measuring tools are needed to verify part accuracy after machining.