In modern packaging operations, the strength of a box is not just a quality parameter; it is a direct indicator of how well a product will survive storage, stacking, and transportation. Corrugated boxes that fail under load can cause product damage, shipment rejection, and financial loss. This is where a box compression tester becomes a critical testing instrument for packaging manufacturers, quality labs, and logistics teams.

A box compression tester is designed to evaluate the compressive strength of corrugated boxes by applying a controlled vertical load until deformation or failure occurs. The data generated from this test helps manufacturers verify whether a box meets required standards and whether it can safely withstand real-world stacking conditions.

What Is a Box Compression Tester?

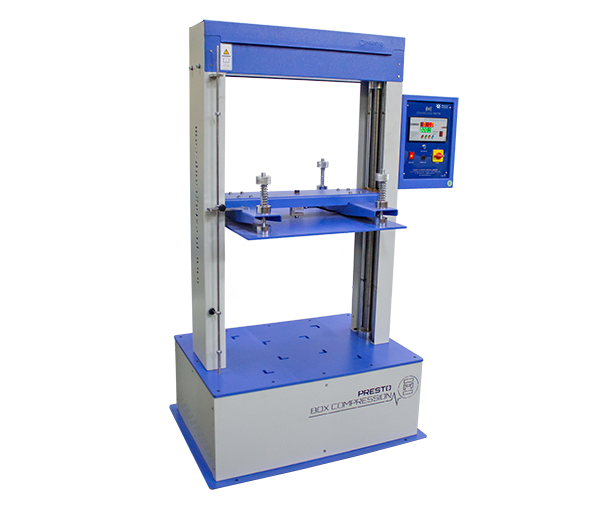

A box compression tester is a laboratory testing machine used to measure the maximum load a box can endure before collapsing. During the test, a corrugated box is placed between two compression plates. The upper plate moves downward at a controlled speed and applies force uniformly on the box. The machine records the maximum force sustained, along with deformation patterns.

This test is commonly referred to as the box compression test (BCT) and is widely used across packaging, paper, food, pharmaceutical, and e-commerce industries. Results from this test are essential for validating packaging design and optimizing material usage.

Why Box Compression Testing Is Important

Packaging failures often occur due to improper box strength rather than poor product quality. When boxes are stacked in warehouses or loaded into containers, they experience constant compressive forces. If the box is not strong enough, it may buckle or collapse, damaging the contents inside.

By using a box compression tester, manufacturers can ensure consistent packaging quality, reduce customer complaints, and meet industry compliance requirements. This testing also helps in reducing over-packaging by selecting the right material strength instead of relying on guesswork.

How a Box Compression Tester Works

The working principle of a box compression tester is straightforward yet highly precise. The box is positioned centrally on the lower compression plate. Once the test starts, the upper plate descends at a predefined speed and applies compressive force. Sensors inside the machine continuously measure the applied load and displacement.

As the force increases, the box begins to deform. The tester records the peak load at which the box either collapses or reaches a predefined deformation limit. This value is displayed digitally and can be stored for analysis and reporting.

Modern digital box compression testers also allow users to set specific test parameters such as load rate, maximum force limit, and pass/fail criteria.

Applications of Box Compression Tester

Box compression testing is widely used in industries where packaging integrity is critical. Corrugated box manufacturers rely on this test to validate box strength before dispatch. E-commerce companies use it to ensure boxes can survive long-distance shipping and stacking during transit.

Food and beverage packaging units use box compression testers to ensure that cartons maintain integrity during cold storage and transportation. Pharmaceutical and medical packaging manufacturers use compression testing to comply with regulatory quality standards and avoid product contamination due to packaging failure.

Standards Followed in Box Compression Testing

Box compression testers are typically designed to comply with international testing standards. Commonly followed standards include ASTM D642, ISO 12048, and TAPPI T804. These standards define test conditions, loading rates, and reporting methods to ensure consistency and reliability across different laboratories.

Compliance with these standards is especially important for exporters and manufacturers supplying to global markets.

Box Compression Tester Manufacturer, Supplier, and Pricing Considerations

When selecting a box compression tester manufacturer or supplier, it is important to consider machine accuracy, load capacity, and long-term reliability. Buyers should also evaluate service support, calibration availability, and compliance with international standards.

Box compression tester price can vary depending on load capacity, automation level, and digital features. Entry-level models suitable for small packaging units are more affordable, while advanced computerised models used in large quality labs may have higher pricing due to enhanced precision and data management capabilities.

Working with a trusted manufacturer ensures accurate results, longer machine life, and consistent after-sales support.

Benefits of Using a Box Compression Tester

Using a box compression tester helps manufacturers reduce packaging failures and product damage. It improves confidence in packaging design and ensures that boxes are strong enough without excessive material usage. This leads to cost savings and improved sustainability.

Consistent compression testing also strengthens brand reputation by ensuring that products reach customers in perfect condition. Over time, this testing becomes a key part of quality assurance systems in packaging operations.

Choosing the Right Box Compression Tester

Selecting the right machine depends on the type of boxes tested, expected load range, and testing frequency. Manufacturers dealing with heavy-duty industrial packaging may require higher load capacity machines, while lightweight corrugated box producers can opt for standard models.

Digital displays, automatic data recording, and safety features are additional factors that enhance usability and testing efficiency.

Conclusion

A box compression tester is an indispensable testing instrument for ensuring packaging strength and reliability. By accurately measuring compressive load capacity, it helps manufacturers design better packaging, reduce losses, and meet industry standards. Whether you are a packaging manufacturer, supplier, or quality control professional, investing in a reliable box compression tester is a strategic step toward consistent product protection.

Leading testing equipment providers such as Presto Group offer advanced box compression testing solutions that meet global quality benchmarks and support a wide range of industrial applications.