The photomask inspection market relies on advanced inspection tools, automation software, and continuous technological developments to ensure defect-free semiconductor production. High-resolution imaging, AI integration, and predictive analytics help fabs detect and classify defects efficiently. Automation software streamlines workflows, improves throughput, and integrates inspection data with fab management systems. Technological advancements enhance accuracy, reduce wafer scrap, and support fabs operating at advanced nodes, making photomask inspection critical for global semiconductor manufacturing efficiency and growth.

Advanced Inspection Tools

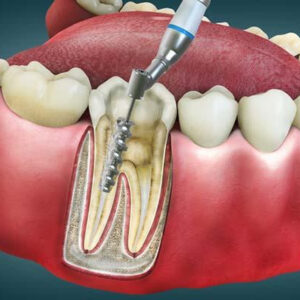

Inspection tools have evolved to meet the demands of complex semiconductor fabrication. Optical and electron beam systems provide nanoscale resolution, enabling precise defect detection. Multi-sensor imaging combines various modalities to enhance defect identification and reduce false positives. Continuous improvements in inspection tools support advanced lithography, higher volume production, and yield optimization.

Automation Software Integration

Automation software optimizes inspection workflows, reduces manual intervention, and ensures consistent defect classification. Integration with fab management systems allows real-time monitoring, process feedback, and predictive maintenance. Automated systems handle high-volume inspections, maintain accuracy, and support throughput optimization, enhancing operational efficiency in semiconductor fabs.

Technological Developments

Technological developments in imaging, AI, and machine learning enhance defect detection and classification. Predictive analytics leverages historical and real-time data to anticipate potential defects and process deviations. Emerging trends, such as edge computing and AI-driven inspection, further improve speed, accuracy, and operational efficiency. Continuous innovation is essential for maintaining competitiveness and meeting evolving fab requirements.

High-Resolution Imaging

High-resolution imaging is crucial for detecting minute defects in photomasks. Optical, electron beam, and multi-sensor technologies provide detailed visualization of nanoscale features. High-resolution inspection ensures accurate defect identification, supports advanced nodes, and reduces wafer-level errors, contributing to higher yield and fab efficiency.

Machine Learning and AI Applications

Machine learning and AI optimize defect detection, classification, and predictive capabilities. Algorithms learn from inspection data, improve accuracy, and reduce false positives. AI-driven solutions enhance yield, support proactive process adjustments, and improve operational efficiency. Adoption of AI and machine learning is growing, enabling fabs to handle increasing semiconductor complexity effectively.

Predictive Analytics for Process Control

Predictive analytics utilizes inspection data to forecast potential defects and process deviations. Early detection allows fabs to implement corrective actions proactively, reducing wafer scrap and enhancing yield. Integration with fab management software ensures real-time insights, enabling continuous process control and operational efficiency.

Process Optimization

Photomask inspection data supports process optimization by identifying recurring defects, deviations, and inefficiencies. Continuous monitoring allows timely corrective actions, reducing downtime and ensuring consistent product quality. Optimized inspection workflows contribute directly to yield improvement, throughput enhancement, and operational excellence in semiconductor fabs.

Deployment Models

Inspection systems are deployed on-premise, cloud-based, or as hybrid solutions. On-premise deployment provides security, compliance, and full control. Cloud-based systems offer scalability, centralized monitoring, and remote access. Hybrid deployments combine both advantages, providing flexibility, real-time analytics, and efficient resource utilization. Deployment choice depends on fab requirements, production scale, and adoption strategy.

Vendor Strategies

Vendors focus on innovation, AI integration, automation software, and high-resolution inspection tools to maintain competitiveness. Strategic partnerships, R&D investments, and advanced product offerings strengthen market positioning. Vendors delivering scalable, accurate, and reliable inspection solutions gain wider adoption and long-term client relationships. Effective strategies address inspection accuracy, throughput optimization, and emerging technological trends.

Market Drivers

Rising semiconductor complexity, shrinking nodes, and increasing global demand drive photomask inspection adoption. High-resolution imaging, automation, AI, and predictive analytics improve inspection accuracy and throughput. Market growth is fueled by technological innovation, operational efficiency requirements, and the need for defect-free masks in semiconductor fabs.

Challenges

Challenges include high equipment costs, integration with legacy systems, and large-scale data management. Balancing throughput and inspection accuracy is critical. Vendors address these challenges with advanced automation, predictive analytics, and AI-driven inspection solutions, ensuring reliable quality control and competitiveness in the market.

Real-Time Monitoring

Real-time monitoring allows immediate detection of defects and process deviations. Continuous inspection provides actionable insights, supports predictive maintenance, and enhances operational efficiency. Integration with fab management systems ensures seamless workflows, higher throughput, and reduced wafer-level errors. Real-time monitoring is essential for maintaining quality and yield in semiconductor manufacturing.

Industry Applications

Photomask inspection tools are used across logic chips, memory devices, and advanced packaging. High-volume semiconductor fabs depend on precise inspection tools to maintain product quality and meet industry standards. Applications in automotive, telecommunications, consumer electronics, and industrial sectors emphasize operational efficiency, defect-free masks, and global competitiveness.

Emerging Trends

Emerging trends include AI-powered inspection, multi-sensor imaging, predictive analytics, and edge computing. These technologies enhance inspection speed, accuracy, and throughput. Adoption of emerging technologies supports fabs in achieving defect-free production, optimizing yield, and reducing operational costs. Continuous innovation strengthens global market adoption.

Market Outlook

The photomask inspection market outlook is promising, driven by inspection tools, automation software, and technological developments. Investment in AI, predictive analytics, high-resolution imaging, and workflow automation ensures operational efficiency, yield improvement, and process reliability. Vendors providing innovative, scalable, and accurate inspection solutions are well-positioned for global market growth in semiconductor manufacturing.

Conclusion

Photomask inspection industry analysis highlights the importance of advanced inspection tools, automation software, and technological developments. High-resolution imaging, AI, and predictive analytics improve defect detection, throughput, and yield. Vendor strategies, process optimization, and emerging trends drive adoption. The market outlook is strong, positioning photomask inspection as a key enabler of semiconductor manufacturing efficiency and global growth.