The UAE’s construction and interior fit-out sector continues to expand, driven by commercial real estate, hospitality projects, and luxury residential developments. According to regional construction market analyses, demand for custom wood components—doors, panels, cabinetry, and decorative elements—has increased steadily over the last decade.

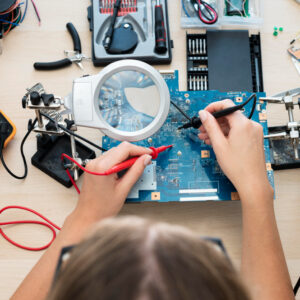

In such an environment, precision errors of even 1–2 mm can result in rework, wasted material, or failed inspections. DIY cutting setups, often built around handheld saws or modified bench tools, struggle to meet the accuracy and repeatability required for large-scale or high-end projects.

Industrial wood cutting machines, by contrast, are engineered for consistency across hundreds or thousands of cuts, even under continuous operation.

Precision and Accuracy: The Core Advantage

Precision is the most immediate differentiator between industrial machines and DIY setups.

DIY Limitations

DIY configurations depend heavily on operator skill. Variations in blade alignment, vibration, feed speed, and material support often lead to:

- Uneven edges

- Inconsistent dimensions

- Burn marks or splintering

- Material wastage

Even experienced operators cannot fully eliminate these variables when using non-industrial tools.

Industrial Machine Performance

An industrial wood cutting machine is designed with:

- Rigid frames to minimize vibration

- Precision-calibrated guides and fences

- Controlled feed mechanisms

- High-torque motors for uniform cutting

Many CNC-based machines can maintain tolerances within ±0.1 mm. For UAE-based manufacturers supplying premium projects, this level of accuracy is not a luxury—it is a requirement.

Productivity and Time Efficiency at Scale

Time efficiency directly impacts profitability, especially in competitive markets like Dubai, Abu Dhabi, and Sharjah.

Output Comparison

A typical DIY setup may process:

- 10–20 panels per hour (with setup adjustments)

An industrial wood cutting machine can process:

- 60–120 panels per hour, depending on material and configuration

That difference compounds rapidly across weeks and months.

Reduced Downtime

Industrial machines are built for continuous operation. Features such as automatic blade cooling, dust extraction integration, and overload protection significantly reduce downtime caused by overheating or mechanical stress—issues common in DIY setups.

Safety Standards and Risk Reduction

Workplace safety regulations in the UAE are becoming increasingly stringent, especially for industrial workshops and manufacturing units.

Risks with DIY Setups

DIY wood cutting arrangements often lack:

- Proper blade guards

- Emergency stop systems

- Anti-kickback mechanisms

- Enclosed cutting zones

This increases the risk of serious injuries, insurance claims, and regulatory penalties.

Industrial Safety Engineering

Industrial wood cutting machines are designed to meet international safety standards and typically include:

- Emergency stop buttons

- Sensor-based blade control

- Enclosed or semi-enclosed cutting areas

- Automated material feeding to reduce manual handling

From a risk management perspective, investing in professional equipment through trusted industrial tools suppliers is far more defensible than relying on improvised solutions.

Cost Efficiency: Looking Beyond Initial Investment

One of the most common arguments in favor of DIY setups is lower upfront cost. However, this view ignores total cost of ownership.

Hidden Costs of DIY Solutions

- Higher material wastage due to inaccurate cuts

- Frequent blade replacements

- Increased labor hours per unit

- Higher accident-related expenses

- Inconsistent output quality leading to rejected work

Industrial ROI Perspective

While industrial wood cutting machines require higher initial investment, they deliver:

- Lower cost per cut

- Longer blade life

- Reduced labor dependency

- Predictable maintenance schedules

Many UAE workshops report a full return on investment within 12–24 months when upgrading from DIY to industrial systems.

Material Versatility and Consistent Quality

DIY setups are typically optimized for limited material types. Cutting hardwood, MDF, plywood, laminated boards, and engineered wood on the same setup often requires frequent adjustments and compromises.

Industrial wood cutting machines are engineered to handle:

- Dense hardwoods

- Laminated and coated boards

- Thick panels and composite materials

- High-volume batch processing

This versatility allows manufacturers to expand service offerings without sacrificing quality or efficiency.

Scalability for Growing Businesses

For businesses planning long-term growth, scalability is critical.

DIY setups reach a performance ceiling quickly. Adding more volume often means:

- Hiring additional operators

- Increasing error rates

- Compromising safety

Industrial machines scale differently. Output increases through automation, software upgrades, or integration with other production systems—without linear increases in labor or risk.

This scalability is especially important in the UAE, where project sizes can expand rapidly and deadlines are often non-negotiable.

The Role of Reliable Industrial Tools Suppliers

The performance of an industrial wood cutting machine is only as strong as the support behind it. Reputable industrial tools suppliers provide:

- Proper machine selection based on workload

- Installation and calibration

- Operator training

- Access to spare parts and service

In contrast, DIY setups rely heavily on self-maintenance and trial-and-error, which can be costly in professional environments.

Final Thoughts: Choosing Performance Over Compromise

DIY wood cutting setups may serve hobbyists or very small workshops, but they are fundamentally misaligned with the demands of professional woodworking in the UAE. Precision, safety, productivity, and scalability are not optional—they are essential for competitiveness and compliance.

An industrial wood cutting machine, sourced from experienced industrial tools suppliers, is not merely a tool upgrade. It is a strategic investment in quality, efficiency, and long-term business resilience.