In the fast-moving world of modern manufacturing, the demand for quality assurance is higher than ever. Yet, maintaining high-speed production while ensuring that every product meets rigorous quality standards is a constant challenge. Traditional manual inspection methods are labor-intensive, inconsistent, and often error-prone, especially when scaling up operations.

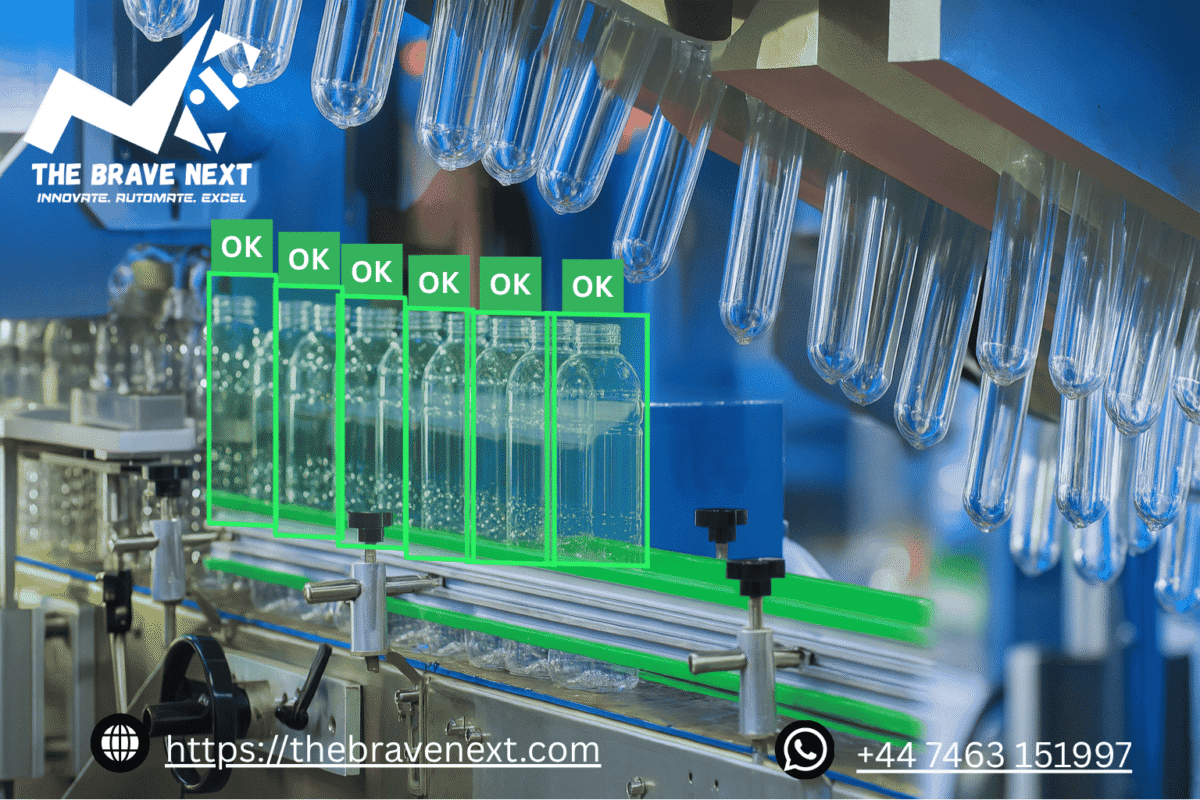

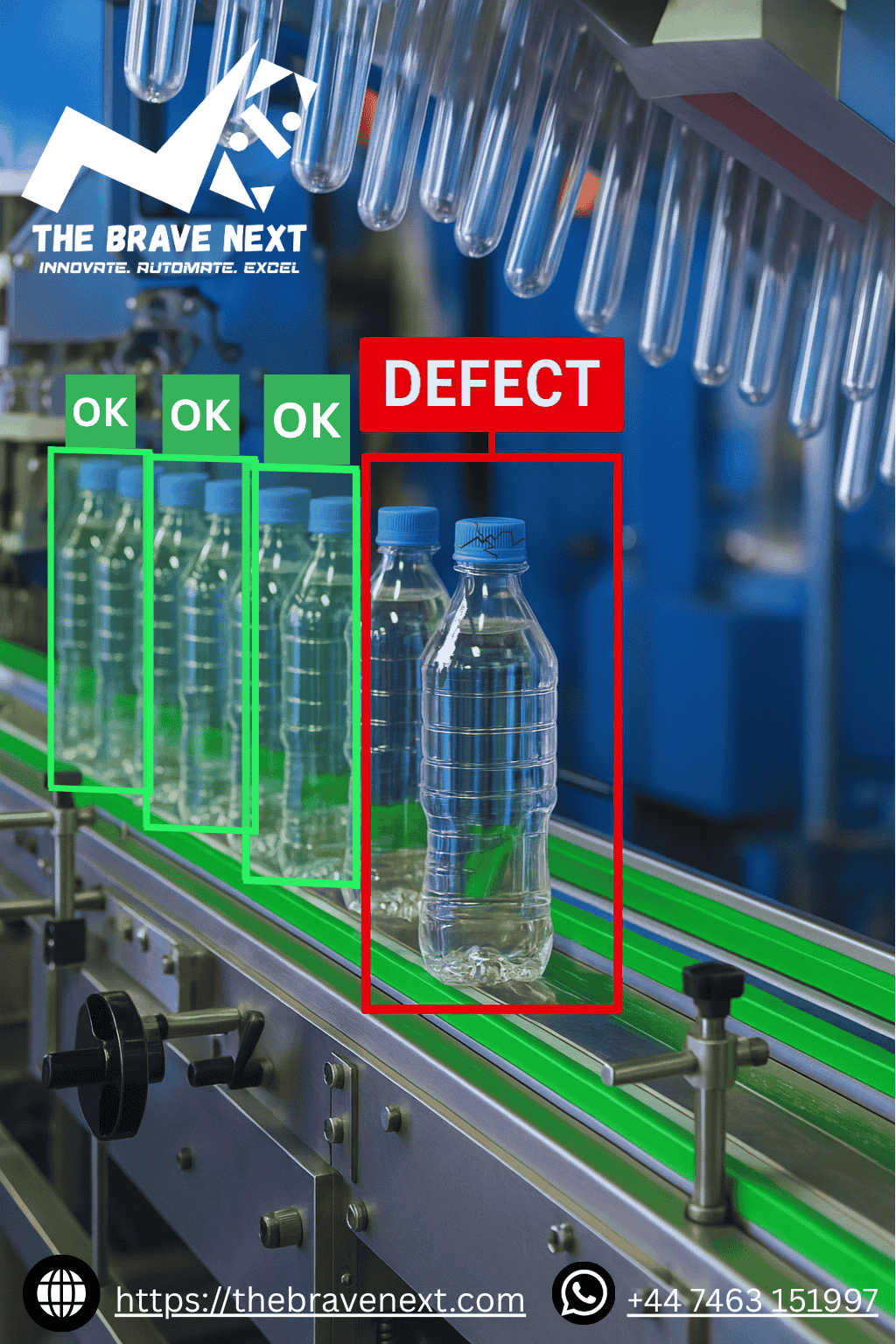

Enter AI-based visual inspection systems — an innovation reshaping how manufacturers approach packaging line quality control. Powered by computer vision and deep learning, these systems are designed to detect minute defects in real-time, enabling smarter, faster, and more reliable inspections across industries.

What Is an AI-Based Visual Inspection System?

An AI-based visual inspection system combines machine vision hardware (such as high-speed cameras and sensors) with deep learning algorithms to automatically detect, classify, and react to visual anomalies in products as they move along the production or packaging line.

Unlike rule-based systems that require pre-programmed parameters, AI systems learn from data. They improve over time by analyzing thousands of labeled images to recognize subtle variations and complex patterns that would be difficult — or even impossible — for human inspectors to catch consistently.

Smarter Quality Control with AI

Traditional inspection methods often involve human operators manually checking for defects such as:

-

Misaligned or missing labels

-

Broken or improperly sealed packaging

-

Discoloration or contamination

-

Incorrect item count or size

-

Barcoding errors

These inspections are time-consuming, prone to fatigue-related errors, and not scalable for high-volume production lines.

AI-based visual inspection systems overcome these limitations. Once trained, they can process hundreds of units per minute, identifying even the most subtle inconsistencies with remarkable accuracy. Deep learning models can distinguish between acceptable natural variation and true defects, reducing false positives and unnecessary rejections.

Real-Time Monitoring for Instant Decision-Making

One of the biggest advantages of AI-powered inspection is real-time decision-making. As products move along the packaging line, the system continuously monitors their quality. When a defect is detected, the system can trigger:

-

Automated rejection mechanisms to remove faulty items from the line

-

Alerts to operators or maintenance teams for rapid troubleshooting

-

Live dashboards displaying performance metrics and defect trends

This immediate feedback loop ensures problems are addressed quickly, minimizing production losses, reducing waste, and protecting brand reputation.

Benefits Across Industries

AI visual inspection is not confined to one industry. Its flexibility makes it ideal for a wide range of sectors, including:

📦 Food & Beverage

Detecting packaging integrity (leaks, incorrect fill levels), missing expiration dates, or contamination. Ensures compliance with health and safety standards.

💊 Pharmaceuticals

Verifying label correctness, dosage accuracy, and packaging seals. Critical for patient safety and regulatory compliance.

🧴 Consumer Goods

Inspecting cosmetic defects, packaging presentation, and barcode readability. Essential for consistent brand image.

🏭 Industrial Manufacturing

Checking part alignment, dimensions, and surface defects in high-speed automated environments.

Easy Integration into Existing Lines

One of the strongest selling points of modern AI inspection systems is ease of deployment. They’re designed to fit into existing production and packaging setups with minimal disruption. Key features include:

-

Modular hardware (custom camera setups for different line speeds and lighting conditions)

-

Scalable software that can be retrained or fine-tuned for new product types

-

Cloud and edge computing options for real-time or centralized data processing

-

API support to integrate with MES (Manufacturing Execution Systems) and ERP systems

Manufacturers no longer need to overhaul their entire line to implement AI; instead, these systems enhance current operations and grow alongside production needs.

Data-Driven Continuous Improvement

Beyond quality control, AI-based systems deliver valuable operational insights. Every image and decision is logged, building a powerful dataset over time. Manufacturers can use this data to:

-

Track defect patterns and trace them back to specific machines or operators

-

Optimize line settings and product design to reduce recurring errors

-

Support predictive maintenance by flagging subtle visual cues of machine wear

-

Generate audit-ready reports for compliance and customer assurance

In short, AI turns inspection from a passive task into a strategic capability.

The ROI of AI-Based Visual Inspection

The return on investment for AI inspection solutions is often seen within months of deployment. Some key ROI factors include:

-

Reduced labor costs due to automation of manual tasks

-

Lower scrap rates and material waste from early detection of defects

-

Fewer product recalls or customer complaints, preserving brand integrity

-

Increased line efficiency by minimizing unplanned downtimes

-

Better compliance with stringent regulatory requirements

These benefits make AI-based inspection a strategic advantage rather than just a technical upgrade.

The Brave Next: Shaping the Future of Smart Manufacturing

At The Brave Next, we’re passionate about exploring how AI and digital transformation are redefining industrial operations. Visual inspection systems represent a key frontier in this transformation — merging deep tech with real-world manufacturing challenges to deliver smarter, safer, and more sustainable results.

Whether you’re in food production, pharmaceuticals, or high-speed consumer goods, AI-based visual inspection empowers your team to innovate, automate, and excel.

Want to see how AI can transform your packaging line?

Visit 🌐 www.thebravenext.com or contact us at 📞 +44 7463 151997.

The Brave Next – Innovate. Automate. Excel.